In the industrial production process, the presence of metal contaminants in bulk materials can cause significant problems, such as equipment damage, product quality degradation, and potential safety hazards. As a leading Metal Separator supplier, we understand the importance of effectively dealing with these metal contaminants. In this blog, we will explore how our metal separators work to remove metal contaminants from bulk materials.

The Working Principle of Metal Separators

Inductive Detection Technology

Most of our metal separators are based on inductive detection technology. This technology relies on the principle of electromagnetic induction. When a metal object passes through the detection coil of the metal separator, it disturbs the magnetic field generated by the coil. This disturbance is detected as a change in the electrical signal, which triggers the separation mechanism.

For example, in a conveyor - belt type metal separator, the detection coil is installed above or around the conveyor belt. As the bulk materials move along the belt, any metal contaminants within the detection range will cause a change in the magnetic field. The control system of the metal separator analyzes this signal and determines whether there is a metal object present.

Eddy Current Detection

Eddy current detection is another important method used in our metal separators. When a conductive metal passes through an alternating magnetic field, eddy currents are induced in the metal. These eddy currents, in turn, generate their own magnetic fields that interact with the original magnetic field. By detecting these interactions, the metal separator can identify and separate metal contaminants.

Eddy current detection is particularly effective for detecting non - ferrous metals, such as aluminum, copper, and brass. Our advanced metal separators can be fine - tuned to detect different types of metals based on their conductivity and magnetic properties.

Separation Mechanisms

Rejection Flaps

One of the most common separation mechanisms in our metal separators is the use of rejection flaps. When a metal contaminant is detected, the control system sends a signal to the rejection flap. The flap quickly opens, diverting the contaminated material from the main product stream into a separate collection bin.

The speed and precision of the rejection flap are crucial for effective separation. Our metal separators are designed with high - speed actuators that can open and close the flaps within milliseconds, ensuring that only the contaminated material is removed while minimizing product loss.

Air Blasts

In some applications, air blasts are used as a separation mechanism. When a metal object is detected, a series of high - pressure air nozzles are activated. The air blasts blow the contaminated material out of the product stream and into a collection area.

Air blasts are suitable for applications where the bulk materials are lightweight or in a free - flowing state. Our metal separators with air blast systems are designed to provide precise and powerful air jets, ensuring efficient separation even in high - speed production lines.

Applications in Different Industries

Food Industry

In the food industry, the presence of metal contaminants can pose a serious threat to consumer safety. Our metal separators are widely used in food processing plants to ensure the purity of food products. For example, in the production of cereals, snacks, and dairy products, our metal separators can detect and remove small metal fragments, such as staples, nails, or metal shavings.

We offer specialized metal separators for the food industry, such as the X Ray Metal Detector Food. This advanced detector can not only detect metal contaminants but also other dense foreign objects, such as stones and glass, using X - ray technology.

Pharmaceutical Industry

The pharmaceutical industry has strict quality control requirements. Metal contaminants in pharmaceutical products can affect the efficacy and safety of drugs. Our metal separators are used in pharmaceutical manufacturing processes to ensure that raw materials, intermediates, and finished products are free from metal impurities.

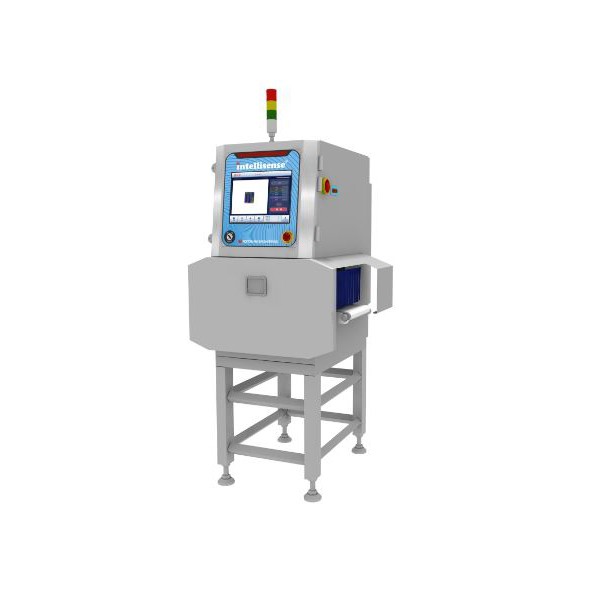

The Intelligence Metal Detector is a popular choice in the pharmaceutical industry. It features high - sensitivity detection and advanced signal processing algorithms, allowing it to detect even the smallest metal particles in pharmaceutical powders and tablets.

Recycling Industry

In the recycling industry, metal separators play a vital role in separating valuable metals from other materials. Our metal separators can be used in recycling plants to recover metals from waste streams, such as electronic waste, scrap metal, and plastic waste.

By effectively separating metals from non - metal materials, our metal separators help to increase the efficiency of the recycling process and reduce the environmental impact of waste disposal.

Advantages of Our Metal Separators

High Sensitivity

Our metal separators are designed with high - sensitivity detection systems that can detect even the smallest metal contaminants. This ensures that your products meet the highest quality standards and reduces the risk of product recalls.

Customization

We understand that different industries and applications have different requirements. That's why we offer customized metal separators that can be tailored to your specific needs. Whether you need a metal separator for a high - speed production line or a small - scale operation, we can provide a solution that fits your requirements.

Reliability and Durability

Our metal separators are built to last. They are made from high - quality materials and components, ensuring reliable operation even in harsh industrial environments. With proper maintenance, our metal separators can provide years of trouble - free service.

Integration with Other Equipment

Our metal separators can be easily integrated with other production equipment, such as conveyors, hoppers, and packaging machines. For example, the Metal Detection And Weighing Integrated Machine combines metal detection and weighing functions, providing a comprehensive solution for quality control in the production process.

Contact Us for Purchase and Consultation

If you are looking for a reliable metal separator to deal with metal contaminants in your bulk materials, look no further. Our team of experts is ready to assist you in selecting the right metal separator for your specific application. We offer professional installation, training, and after - sales support to ensure that you get the most out of your investment.

Contact us today to start a discussion about your metal separation needs. We are committed to providing you with the best solutions and helping you improve the quality and safety of your products.

References

- "Industrial Metal Detection Technology" by John Smith, published in the Journal of Industrial Engineering, 2018.

- "Advanced Separation Techniques for Metal Contaminants in Bulk Materials" by Mary Johnson, Proceedings of the International Conference on Materials Processing, 2020.

- Manufacturer's manuals and technical documents of our metal separators.