In the manufacturing and quality control sectors, the reliability and precision of detection equipment are of utmost importance. Among these, the Metal Needle Inspector stands out as a critical tool, especially in industries where the presence of metal needles can pose significant risks, such as the textile, food, and toy industries. One of the key performance indicators of a Metal Needle Inspector is its detection repeatability. In this blog, as a supplier of Metal Needle Inspectors, I will delve into what detection repeatability means, why it matters, and how our products ensure high - level repeatability.

Understanding Detection Repeatability

Detection repeatability refers to the ability of a Metal Needle Inspector to consistently detect metal needles under the same operating conditions. When a sample with a known metal needle is passed through the inspector multiple times, the equipment should give the same detection result each time. This consistency is crucial because it reflects the stability and accuracy of the detector.

Imagine a textile factory where hundreds of garments are inspected every day for the presence of metal needles. If the Metal Needle Inspector has poor repeatability, it may miss a needle in one inspection and detect it in another. This inconsistency can lead to faulty products being shipped to customers, which can result in serious consequences, such as injuries to consumers and damage to the company's reputation.

Factors Affecting Detection Repeatability

Several factors can influence the detection repeatability of a Metal Needle Inspector.

Sensor Quality

The sensor is the heart of the Metal Needle Inspector. High - quality sensors are more sensitive and stable, which can improve the repeatability of detection. Our Metal Needle Inspectors are equipped with advanced sensors that are designed to accurately detect even the smallest metal needles. These sensors are calibrated to maintain their performance over time, ensuring consistent detection results.

Environmental Conditions

Environmental factors such as temperature, humidity, and electromagnetic interference can affect the performance of the Metal Needle Inspector. Extreme temperatures can cause the components of the detector to expand or contract, which may change the sensitivity of the sensor. Humidity can also lead to corrosion of the internal parts, affecting the accuracy of detection. Our products are designed to be resistant to environmental changes. They are equipped with temperature - and humidity - control mechanisms and shielding to reduce the impact of electromagnetic interference.

Product Design and Construction

The design and construction of the Metal Needle Inspector also play an important role in detection repeatability. A well - designed inspector will have a stable mechanical structure and a proper signal processing system. Our Metal Needle Inspectors are engineered with a rigid frame to prevent vibration and ensure that the samples pass through the detection area smoothly. The signal processing system is optimized to filter out noise and enhance the detection signal, improving the repeatability of the detection.

How Our Metal Needle Inspectors Ensure High Detection Repeatability

We, as a professional supplier of Metal Needle Inspectors, have taken several measures to ensure high detection repeatability.

Rigorous Quality Control

We implement strict quality control procedures throughout the production process. Each Metal Needle Inspector undergoes multiple tests and calibrations before leaving the factory. We use standard test samples with known metal needles to verify the detection performance of the equipment. Only when the inspector meets our high - quality standards can it be shipped to customers.

Continuous Research and Development

We invest heavily in research and development to improve the performance of our Metal Needle Inspectors. Our R & D team is constantly exploring new technologies and materials to enhance the sensitivity and stability of the sensors. We also update the signal processing algorithms to adapt to different detection requirements and improve the repeatability of detection.

Customer - Oriented Service

We provide comprehensive after - sales service to our customers. Our technical support team is always ready to help customers solve any problems they may encounter with the Metal Needle Inspectors. We also offer regular maintenance and calibration services to ensure that the equipment maintains its high - level performance over time.

Types of Our Metal Needle Inspectors and Their Repeatability

We offer a variety of Metal Needle Inspectors to meet the different needs of our customers.

Double Probe Needle Detector

The Double Probe Needle Detector is designed with two probes, which can significantly improve the detection accuracy and repeatability. The two probes work in tandem to detect metal needles from different angles, reducing the possibility of false negatives. This detector is suitable for industries that require high - precision detection, such as the medical and electronic industries.

Non Driving Non - woven Needle Detector

The Non Driving Non - woven Needle Detector is specifically designed for the non - woven fabric industry. It has a unique design that allows non - woven fabrics to pass through the detection area smoothly without being damaged. The detector uses advanced sensors and signal processing technology to ensure high - level detection repeatability, even when dealing with large - volume non - woven fabric production.

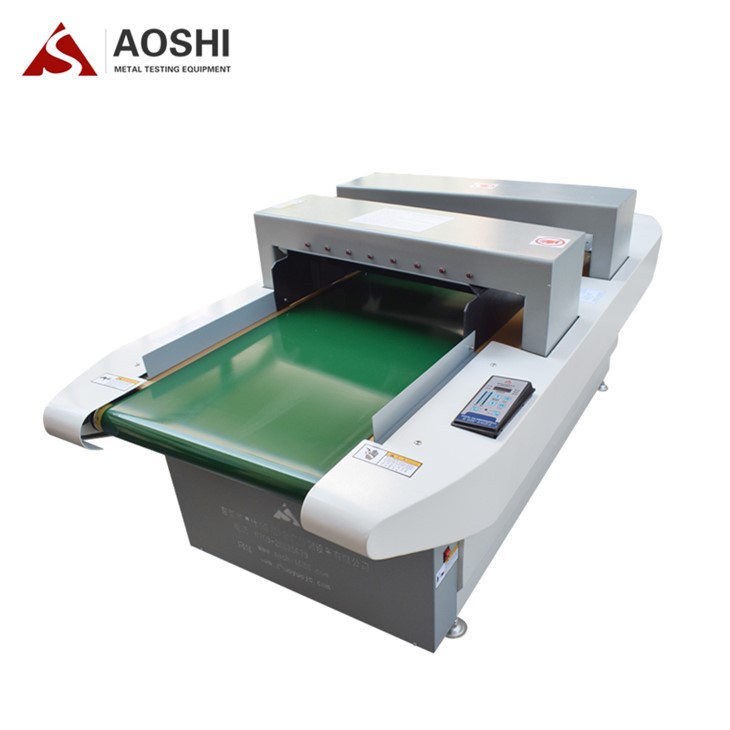

Metal Needle Inspector

Our general - purpose Metal Needle Inspector is suitable for a wide range of industries, including textile, food, and toy industries. It is easy to operate and maintain, and it offers excellent detection repeatability. The inspector is equipped with a user - friendly interface that allows operators to adjust the detection parameters according to their specific needs.

Importance of Detection Repeatability in Different Industries

Textile Industry

In the textile industry, the presence of metal needles in garments can cause serious harm to consumers. A Metal Needle Inspector with high detection repeatability can ensure that all garments are free of metal needles before being shipped. This not only protects the safety of consumers but also helps textile manufacturers maintain a good reputation in the market.

Food Industry

In the food industry, metal needles can contaminate food products, posing a health risk to consumers. Our Metal Needle Inspectors with high repeatability can detect metal needles in food products accurately and consistently, ensuring the safety and quality of food.

Toy Industry

Toys are often used by children, and the presence of metal needles in toys can cause injuries. A reliable Metal Needle Inspector can help toy manufacturers meet the strict safety standards and ensure the safety of children.

Conclusion

Detection repeatability is a crucial performance indicator of a Metal Needle Inspector. As a supplier of Metal Needle Inspectors, we understand the importance of this factor and have taken various measures to ensure that our products offer high - level detection repeatability. Our range of Metal Needle Inspectors, including the Double Probe Needle Detector, Non Driving Non - woven Needle Detector, and Metal Needle Inspector, are designed to meet the different needs of various industries.

If you are looking for a reliable Metal Needle Inspector with high detection repeatability, please feel free to contact us for more information and to discuss your specific requirements. We are committed to providing you with the best products and services to ensure the quality and safety of your products.

References

- Smith, J. (2018). Quality Control in Manufacturing: The Role of Metal Detectors. Journal of Manufacturing Technology, 25(3), 123 - 135.

- Johnson, M. (2019). Advances in Metal Detection Technology. Proceedings of the International Conference on Industrial Automation, 45 - 52.

- Brown, K. (2020). Ensuring Product Safety with Metal Needle Inspectors. Food Safety Magazine, 15(2), 67 - 72.