Hey there! As a supplier of Metal Needle Detectors, I often get asked if these devices can be used in jewelry manufacturing. Well, the short answer is yes, and in this blog, I'll explain why and how they fit into the jewelry - making process.

Why Jewelry Manufacturing Needs Metal Needle Detectors

First off, let's understand the importance of quality control in jewelry manufacturing. Jewelry is not just an accessory; it's often a significant investment for consumers. Whether it's a diamond ring for an engagement or a gold necklace for a special occasion, customers expect perfection.

One of the biggest concerns in jewelry production is the presence of foreign metal objects. These could be tiny steel needles that might have accidentally fallen into the production area, or small fragments of metal tools. If these foreign objects end up in the finished jewelry, it can cause a whole host of problems. For one, it can scratch or damage the precious metals and gemstones. Imagine a beautiful diamond getting chipped because of a stray metal piece!

Secondly, from a safety perspective, a sharp metal needle in a piece of jewelry can pose a serious risk to the wearer. It could pierce the skin, leading to injuries and potential infections. So, to ensure the quality and safety of the jewelry, using a metal needle detector is a no - brainer.

How Metal Needle Detectors Work in Jewelry Manufacturing

Metal needle detectors operate on the principle of electromagnetic induction. When a piece of jewelry passes through the detector, the electromagnetic field around the detector is disturbed if there is a metal object present. The detector then signals an alarm, indicating the presence of the foreign metal.

In a jewelry manufacturing setting, these detectors can be used at various stages of the production process. For instance, at the raw material stage, when the precious metals are being sourced and prepared, a metal needle detector can be used to check for any impurities or foreign metal pieces in the ingots or wires. This helps in maintaining the purity of the materials right from the start.

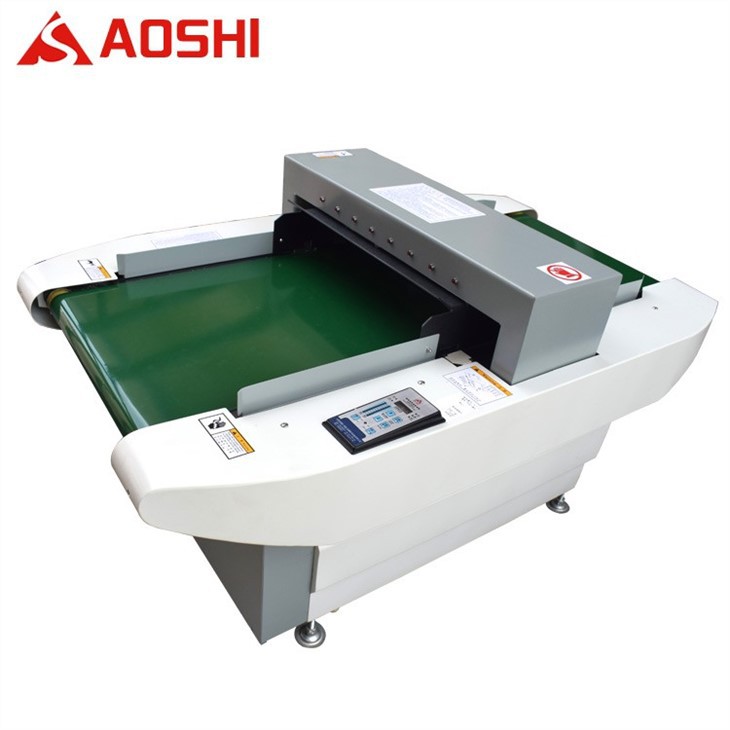

During the assembly process, when different components of the jewelry are being put together, the detector can be placed on the conveyor belt or workbench. As the semi - finished pieces move along, the detector can quickly identify any metal needles or fragments that might have been introduced during the soldering, setting, or other assembly operations.

Even at the final inspection stage, a metal needle detector can be used to give the finished jewelry a final once - over. This ensures that every piece leaving the factory is free from any unwanted metal objects, meeting the high - quality standards expected by the customers.

Types of Metal Needle Detectors Suitable for Jewelry Manufacturing

There are several types of metal needle detectors that are well - suited for jewelry manufacturing. One popular option is the Long Strip Needle Inspection Machine. This machine is designed to handle long and narrow pieces of jewelry, such as chains or bracelets. It has a high - sensitivity detection system that can accurately identify even the smallest metal needles.

Another great choice is the Metal Needle Inspector. This is a more versatile detector that can be used for a wide range of jewelry items, from rings to pendants. It offers adjustable sensitivity settings, allowing the manufacturers to customize the detection level based on the type of jewelry being produced.

For non - woven materials that are sometimes used in jewelry packaging or as backing for gemstones, the Non Driving Non - woven Needle Detector is an excellent option. It can detect metal needles in non - woven fabrics without the need for a driving mechanism, making it a convenient and efficient choice for jewelry manufacturers.

Benefits of Using Our Metal Needle Detectors

As a supplier, I'm proud to say that our metal needle detectors come with several benefits. Firstly, they are highly sensitive. Our detectors can detect even the tiniest metal needles, ensuring that no foreign metal object goes unnoticed. This high level of sensitivity is crucial in the jewelry industry, where the quality standards are extremely high.

Secondly, our detectors are easy to operate. They come with user - friendly interfaces and clear instructions, so even new employees in the jewelry manufacturing facility can quickly learn how to use them. This reduces the training time and increases the overall efficiency of the production process.

We also offer excellent after - sales support. If there are any issues with the detector, our team of experts is always ready to provide assistance. Whether it's troubleshooting, maintenance, or calibration, we've got you covered.

Cost - Effectiveness of Using Metal Needle Detectors

Some jewelry manufacturers might be hesitant to invest in a metal needle detector, thinking it's an additional cost. However, in the long run, using a detector can actually save a lot of money. By preventing defective jewelry from reaching the market, manufacturers can avoid costly product recalls. A product recall not only means losing the revenue from the returned products but also damages the brand reputation, which can be even more expensive to repair.

Moreover, by ensuring the quality of the jewelry, manufacturers can command higher prices for their products. Customers are willing to pay more for jewelry that they know is safe and of high quality. So, the investment in a metal needle detector is well worth it.

Conclusion

In conclusion, metal needle detectors are an essential tool in jewelry manufacturing. They play a crucial role in ensuring the quality, safety, and purity of the jewelry. By using these detectors at various stages of the production process, jewelry manufacturers can avoid potential risks, maintain high - quality standards, and ultimately, increase customer satisfaction.

If you're in the jewelry manufacturing business and are looking for a reliable metal needle detector, I'd love to have a chat with you. We offer a wide range of detectors that can be customized to meet your specific needs. Don't hesitate to reach out to start a procurement discussion and take your jewelry manufacturing quality to the next level.

References

- "Industrial Metal Detection Handbook" - A comprehensive guide on the working principles and applications of metal detectors in various industries.

- "Quality Control in Jewelry Manufacturing" - A research paper discussing the importance of quality control measures in the jewelry industry.