Can a garment needle detector be customized according to specific needs? Well, let me tell you, as a garment needle detector supplier, the answer is a big yes!

In the garment industry, safety is super important. No one wants a needle to end up in a piece of clothing that's going to be worn by a customer. That's where our garment needle detectors come in. But different businesses have different needs, and that's why customization is such a great option.

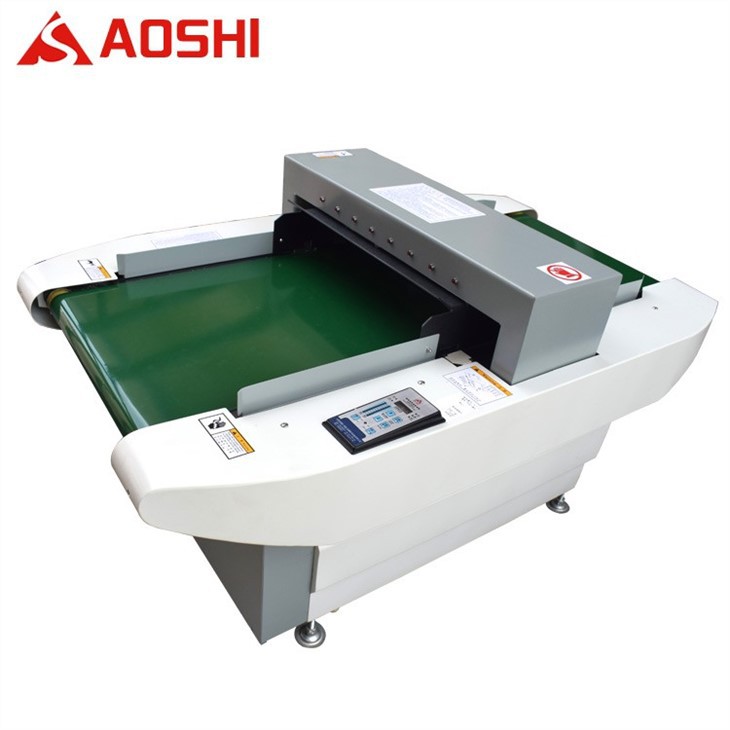

First off, let's talk about the basic functions of a garment needle detector. These machines are designed to find metal needles that might be left in garments during the manufacturing process. They use advanced sensor technology to detect even the tiniest bits of metal. Once a needle is detected, the machine can stop the conveyor belt or give an alarm, depending on how it's set up.

But what if you have a special production line? Maybe you're dealing with larger or smaller garments, or you have a unique layout. That's when customization becomes essential. For example, some of our customers have asked for a Metal Needle Inspector with a different size of detection area. If you're making big coats or blankets, you'll need a wider detection area to make sure the whole item gets checked properly. On the other hand, if you're working on small accessories like socks or gloves, a smaller and more precise detector might be what you need.

Another aspect of customization is the sensitivity of the detector. Different types of fabrics and manufacturing processes can affect how easy it is to detect needles. Some fabrics might have a bit of metal in them naturally, like those with metallic threads. In these cases, you don't want the detector to go off every time it senses a tiny bit of metal. So, we can adjust the sensitivity of the machine to make sure it only alerts you when there's a real needle.

The speed of the detector is also something that can be customized. If your production line is running at a high speed, you need a detector that can keep up. We can optimize the machine to work at the right speed for your specific production volume. This way, you don't have to slow down your production just to check for needles.

We also understand that some customers might need a special interface for their needle detector. Maybe you want it to be integrated with your existing production management system. We can work on customizing the control panel and the software to make it compatible with your other equipment. This makes it easier for your workers to operate the machine and get the information they need.

For those who have a unique workspace, we offer different types of detectors, like the High Gantry Needle Detector. This type of detector is great if you have tall or bulky items to check. It has a high clearance, so you can easily pass large garments through it. And if you're dealing with wide pieces of fabric, our Wide Width Needle Inspection Machine is the perfect solution. It can cover a large width, ensuring that every part of the fabric is inspected.

When it comes to customization, we don't just stop at the hardware. We also provide training and support to make sure you get the most out of your customized detector. Our team of experts will work with you from the beginning to understand your needs and come up with the best solution. We'll install the machine for you and show your workers how to use it properly. And if you ever have any questions or run into any problems, we're just a call away.

In conclusion, a garment needle detector can definitely be customized according to specific needs. Whether it's the size, sensitivity, speed, or interface, we have the expertise and the technology to make it happen. If you're in the garment industry and are looking for a needle detector that fits your unique requirements, don't hesitate to get in touch with us. We're here to help you improve the safety and efficiency of your production line. Let's work together to find the perfect solution for your business.

References

- Industry research on garment safety standards

- Internal records of customer customization requests and solutions