Hey there! As a supplier of food metal detectors, I'm super stoked to chat with you about the safety features of these nifty machines. Food safety is no joke, and metal detectors play a crucial role in making sure the food we munch on is free from any unwanted metallic contaminants. So, let's dive right in!

1. High - Sensitivity Detection

One of the most important safety features of a food metal detector is its high - sensitivity detection. These machines are designed to pick up even the tiniest bits of metal in food products. Whether it's a small piece of stainless steel, aluminum, or ferrous metal, a good food metal detector can spot it.

The sensitivity is adjustable, which is really handy. Different food products may require different levels of sensitivity. For example, a fine - ground spice might need a higher sensitivity setting compared to a large - chunked meat product. This way, we can ensure that no matter what type of food we're dealing with, we can detect any metal that shouldn't be there.

This high - sensitivity detection is achieved through advanced sensor technology. The sensors are calibrated to detect the unique electromagnetic properties of metals. When a metal object passes through the detection area of the machine, it disrupts the electromagnetic field, and the detector alerts us. This early detection helps prevent contaminated food from reaching the market, protecting consumers from potential harm.

2. Multiple Metal Detection Capabilities

Food metal detectors are not just limited to detecting one type of metal. They can detect a wide range of metals, including ferrous metals (like iron), non - ferrous metals (such as aluminum and copper), and even stainless steel.

In the food industry, different types of metals can end up in products for various reasons. For instance, during the manufacturing process, machinery parts made of different metals might wear out and break off into the food. A food metal detector that can detect multiple types of metals provides comprehensive protection.

This multi - metal detection feature is essential because it covers all possible scenarios. We don't want to miss out on detecting a certain type of metal just because our detector isn't capable of it. By having a detector that can handle different metals, we can be more confident in the safety of our food products.

3. Rejection Systems

Once a metal contaminant is detected, a food metal detector needs to have an effective way to remove the contaminated product from the production line. That's where rejection systems come in.

There are several types of rejection systems available. One common type is the air - blast rejection system. When the detector senses a metal object, it triggers a blast of air that blows the contaminated product off the conveyor belt. This is a quick and efficient way to separate the bad product from the good ones.

Another type is the push - arm rejection system. A mechanical arm pushes the contaminated item off the conveyor. These rejection systems are designed to work fast, so they don't disrupt the flow of the production line too much.

The reliability of the rejection system is crucial. It needs to work every time a metal is detected. Otherwise, contaminated products could continue down the line and end up on store shelves. That's why we test and maintain these rejection systems regularly to ensure they're in top - notch condition.

4. Easy Cleaning and Sanitation

In the food industry, cleanliness is next to godliness. Food metal detectors need to be easy to clean and sanitize to prevent the growth of bacteria and other pathogens.

Most modern food metal detectors are designed with smooth surfaces and minimal crevices. This makes it easier to wipe down and clean the machine. Some detectors also have removable parts that can be taken out and washed separately.

Regular cleaning and sanitation are not only important for food safety but also for the proper functioning of the detector. If dirt and debris build up on the sensors or other components, it can affect the detector's performance. So, having a detector that's easy to clean is a big plus.

5. Self - Testing and Monitoring

A good food metal detector should be able to test itself regularly to make sure it's working correctly. Self - testing features check the performance of the sensors, the rejection system, and other critical components.

These self - tests can be set to run at regular intervals, like every few hours or at the start of each production shift. If the detector detects any issues during the self - test, it will alert the operator immediately. This allows for quick troubleshooting and maintenance, reducing the risk of undetected metal contaminants.

In addition to self - testing, many food metal detectors also have monitoring capabilities. They can collect data on the number of detections, the types of metals detected, and other important information. This data can be used to analyze the performance of the production process and identify any potential areas for improvement.

6. Compliance with Industry Standards

Food metal detectors need to comply with various industry standards and regulations. These standards are in place to ensure the safety and quality of food products.

For example, in the United States, the Food and Drug Administration (FDA) has strict guidelines regarding food safety. A food metal detector that meets these standards gives us peace of mind, knowing that we're following the rules and providing safe food to consumers.

Compliance also means that the detector has been tested and certified to meet certain performance criteria. This includes things like sensitivity levels, accuracy of detection, and the reliability of the rejection system. When choosing a food metal detector, it's important to make sure it meets all the relevant industry standards.

7. Customization Options

Every food production facility is different, and they may have specific requirements for their metal detectors. That's why many food metal detector suppliers, like us, offer customization options.

We can customize the detector's sensitivity settings, the type of rejection system, and even the size and shape of the machine to fit the specific needs of the production line. For example, if a facility has limited space, we can provide a compact metal detector that can be easily integrated into the existing setup.

Customization also allows us to tailor the detector to the specific types of food products being produced. Some products may require special detection algorithms or additional features to ensure accurate detection. By offering customization, we can provide a more personalized solution for our customers.

Let's Connect!

If you're in the market for a high - quality food metal detector with all these amazing safety features, we'd love to hear from you. Whether you're running a small food business or a large - scale production facility, we have the right solution for you.

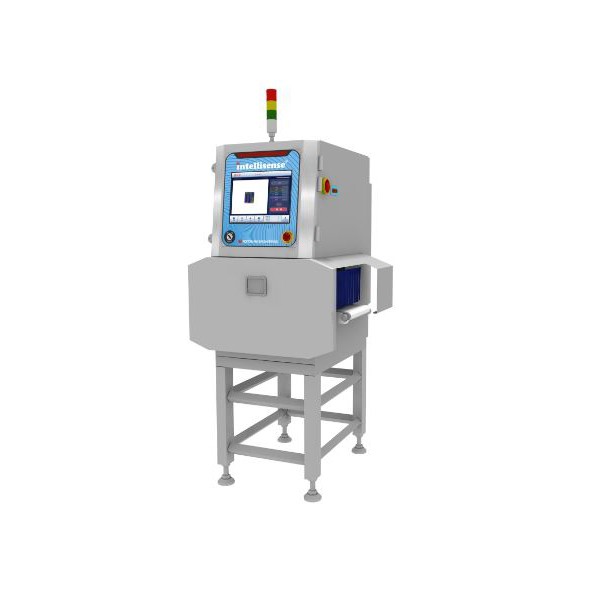

You can check out some of our advanced products like the X Ray Metal Detector Food, which offers even more precise detection capabilities. If you're dealing with Aluminum foil bagged product metal detector, we've got you covered. And for those looking for an all - in - one solution, our Metal Detection And Weighing Integrated Machine is a great option.

Contact us today to start a conversation about your food metal detection needs. We're here to help you ensure the safety and quality of your food products.

References

- "Food Safety and Metal Detection" - Food Industry Journal

- "Advanced Metal Detection Technologies in the Food Sector" - International Food Science Research Report