Can metal alarms be recycled? This is a question that has been on the minds of many in the industry, and as a supplier of metal alarms, I've delved deep into this topic. In this blog, I'll share my insights on the recyclability of metal alarms, the processes involved, and why it matters.

Understanding Metal Alarms

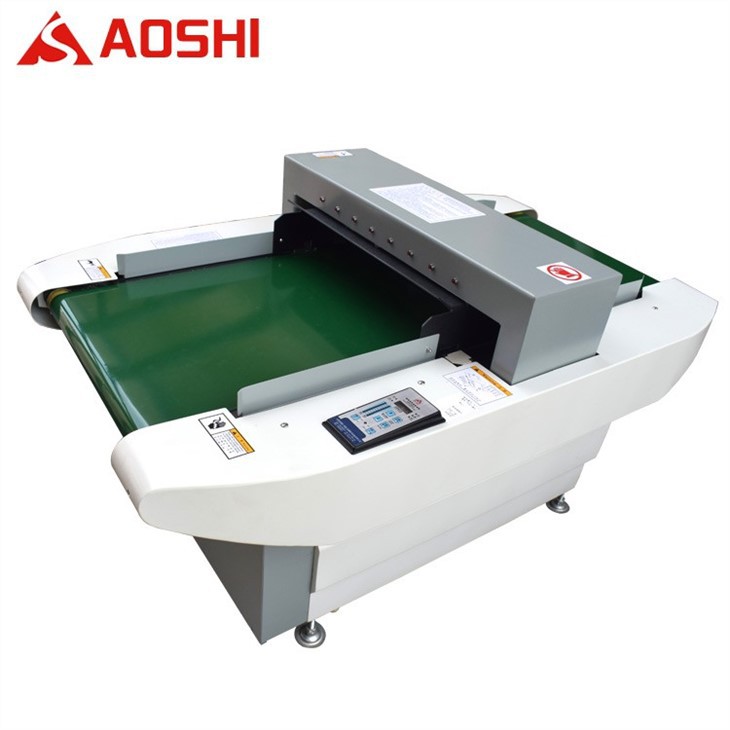

Metal alarms, also known as metal detectors, are essential devices used in various industries, from food production to textile manufacturing. They play a crucial role in ensuring product safety by detecting the presence of metal contaminants. As a supplier, I offer a range of metal alarms, including the Non Driving Non-woven Needle Detector, Long Strip Needle Inspection Machine, and Metal Needle Inspector. These devices are made up of different components, including metal parts, electronic circuits, and plastic casings.

The Recyclability of Metal Alarms

The good news is that many parts of metal alarms can be recycled. Metal components, such as steel, aluminum, and copper, are highly recyclable. Recycling these metals not only conserves natural resources but also reduces the energy required to produce new metal products. Electronic circuits, on the other hand, contain valuable metals like gold, silver, and palladium, which can be recovered through specialized recycling processes.

Plastic casings can also be recycled, although the process is more complex. Different types of plastics have different melting points and properties, so they need to be sorted and processed separately. However, with the right technology and infrastructure, plastic recycling can significantly reduce the environmental impact of metal alarms.

The Recycling Process

The recycling process for metal alarms typically involves several steps. First, the devices are collected and transported to a recycling facility. At the facility, they are disassembled, and the different components are separated. Metal parts are then shredded and melted down to be used in the production of new metal products.

Electronic circuits are sent to specialized recycling plants, where they undergo a process called smelting. During smelting, the circuits are heated to high temperatures, and the valuable metals are separated from the other components. The recovered metals are then refined and purified to be used in the electronics industry.

Plastic casings are sorted by type and then shredded into small pieces. These pieces are then melted and molded into new plastic products, such as plastic lumber or automotive parts.

The Benefits of Recycling Metal Alarms

Recycling metal alarms offers several benefits, both for the environment and the economy. From an environmental perspective, recycling reduces the amount of waste sent to landfills, conserves natural resources, and reduces energy consumption. It also helps to minimize the environmental impact of mining and metal production, which can have significant negative effects on the ecosystem.

Economically, recycling metal alarms can create jobs in the recycling and manufacturing industries. It also reduces the cost of producing new metal and plastic products, as recycled materials are often cheaper than virgin materials. Additionally, recycling can help to meet the growing demand for sustainable products, which is becoming increasingly important to consumers.

Challenges in Recycling Metal Alarms

While the recyclability of metal alarms is promising, there are still some challenges that need to be addressed. One of the main challenges is the lack of awareness among consumers and businesses about the importance of recycling metal alarms. Many people are not aware that these devices can be recycled, or they don't know how to properly dispose of them.

Another challenge is the complexity of the recycling process. Recycling metal alarms requires specialized equipment and expertise, which can be expensive to acquire and maintain. Additionally, the recycling industry is still relatively new, and there is a lack of standardized processes and regulations for recycling electronic waste.

Overcoming the Challenges

To overcome these challenges, it is essential to raise awareness about the importance of recycling metal alarms. As a supplier, I can play a crucial role in educating my customers about the recyclability of my products and providing them with information on how to properly dispose of them. I can also work with recycling facilities and government agencies to develop more efficient and cost-effective recycling processes.

In addition, the government can play a role in promoting the recycling of metal alarms by implementing policies and regulations that encourage recycling. This could include providing incentives for businesses to recycle, setting up collection programs, and investing in research and development to improve the recycling technology.

Conclusion

In conclusion, metal alarms can be recycled, and recycling them offers significant benefits for the environment and the economy. By recycling the metal, electronic, and plastic components of metal alarms, we can conserve natural resources, reduce energy consumption, and minimize the environmental impact of waste disposal. However, there are still some challenges that need to be addressed, such as the lack of awareness and the complexity of the recycling process.

As a supplier of metal alarms, I am committed to promoting the recycling of my products and working with my customers and partners to develop more sustainable solutions. I encourage you to join me in this effort by recycling your old metal alarms and supporting the use of recycled materials in new products.

If you are interested in purchasing metal alarms or have any questions about our products, please feel free to contact me for more information. We are always happy to assist you with your metal detection needs and discuss the best solutions for your business.

References

- "Recycling of Electronic Waste: A Review," Journal of Hazardous Materials, 2018.

- "The Benefits of Recycling Metals," American Iron and Steel Institute, 2020.

- "Plastic Recycling: Challenges and Opportunities," Environmental Science & Technology, 2019.