As a leading supplier of Metal Needle Inspectors, I'm often asked about the signal processing methods employed in these crucial machines. In this blog post, I'll delve into the technical details of how Metal Needle Inspectors process signals to detect metal needles accurately, ensuring the safety and quality of various products.

The Basics of Metal Needle Inspection

Metal Needle Inspectors are essential in industries where the presence of metal needles can pose a significant risk to consumers, such as the textile, food, and pharmaceutical industries. These machines use advanced technology to detect even the smallest metal needles hidden within products, preventing potential hazards and ensuring compliance with safety standards.

The fundamental principle behind metal needle inspection is the interaction between a magnetic field and metal objects. When a metal needle passes through the inspection area of a Metal Needle Inspector, it disturbs the magnetic field, generating a signal that can be detected and analyzed.

Signal Generation in Metal Needle Inspectors

The first step in the signal processing method of a Metal Needle Inspector is the generation of a stable magnetic field. Most Metal Needle Inspectors use electromagnetic coils to create a magnetic field in the inspection area. When a metal object, such as a needle, enters this magnetic field, it induces eddy currents in the metal. These eddy currents, in turn, generate a secondary magnetic field that opposes the original magnetic field, causing a change in the magnetic flux.

The change in magnetic flux is detected by the sensor coils in the Metal Needle Inspector. These coils are designed to be highly sensitive to even the slightest changes in the magnetic field. As the metal needle passes through the inspection area, the sensor coils pick up the induced magnetic field and convert it into an electrical signal.

Signal Amplification and Filtering

Once the electrical signal is generated, it is typically very weak and may be contaminated with noise from various sources, such as electrical interference and mechanical vibrations. To improve the signal-to-noise ratio and make the signal more suitable for further processing, the electrical signal is first amplified using an amplifier circuit.

After amplification, the signal is passed through a series of filters to remove unwanted noise and interference. Low-pass filters are commonly used to eliminate high-frequency noise, while band-pass filters can be used to isolate the frequency range of the signal generated by metal needles. By filtering out the noise, the signal becomes clearer and easier to analyze.

Signal Analysis and Detection

The next step in the signal processing method is to analyze the filtered signal to determine whether a metal needle is present. This is typically done using a combination of analog and digital signal processing techniques.

In analog signal processing, the amplified and filtered signal is compared to a predefined threshold. If the signal exceeds the threshold, it is considered a potential detection of a metal needle. However, analog signal processing alone may not be sufficient to accurately distinguish between metal needles and other metal objects or false signals.

To improve the accuracy of detection, digital signal processing techniques are often employed. Digital signal processing involves converting the analog signal into a digital format using an analog-to-digital converter (ADC). Once in digital form, the signal can be analyzed using algorithms and software.

One common digital signal processing technique used in Metal Needle Inspectors is pattern recognition. By analyzing the shape, amplitude, and frequency characteristics of the signal, the pattern recognition algorithm can identify the unique signature of a metal needle and distinguish it from other objects.

Another important aspect of signal analysis is the use of multiple sensors. Many Metal Needle Inspectors are equipped with multiple sensor coils arranged in different configurations. By analyzing the signals from multiple sensors simultaneously, the machine can improve the accuracy of detection and reduce the likelihood of false alarms.

Signal Classification and Alarm Generation

Once a potential detection of a metal needle is identified, the signal processing system needs to classify the detection as either a true positive or a false positive. This is typically done by comparing the detected signal with a database of known metal needle signals. If the detected signal matches the characteristics of a metal needle signal in the database, it is classified as a true positive, and an alarm is generated.

The alarm can be in the form of a visual indicator, such as a flashing light, or an audible signal, such as a buzzer. In addition to generating an alarm, the Metal Needle Inspector may also be programmed to stop the production line or reject the product containing the metal needle to prevent it from reaching the market.

Our Product Range

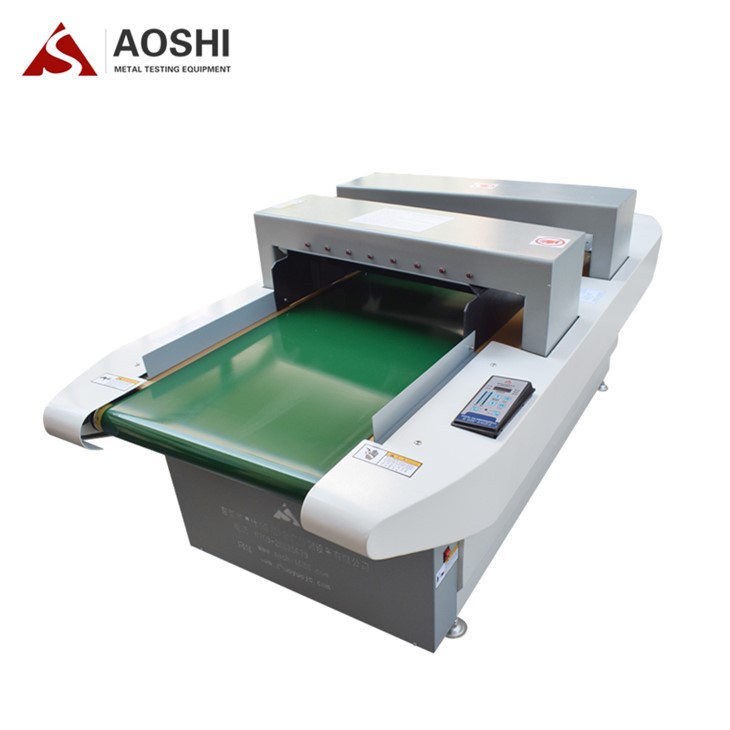

At our company, we offer a wide range of Metal Needle Inspectors to meet the diverse needs of our customers. Our Double Probe Needle Detector is designed for high-speed production lines and provides enhanced detection sensitivity. The High Gantry Needle Detector is suitable for inspecting large and bulky products, while the Wide Width Needle Inspection Machine is ideal for inspecting wide-width materials.

Contact Us for Purchase and Consultation

If you are interested in learning more about our Metal Needle Inspectors or would like to discuss your specific requirements, please feel free to contact us. Our team of experts is always ready to provide you with detailed information and assist you in choosing the right Metal Needle Inspector for your application. We look forward to working with you to ensure the safety and quality of your products.

References

- Smith, J. (2018). Principles of Metal Detection. Wiley.

- Jones, A. (2020). Signal Processing for Industrial Sensors. IEEE Press.