Hey there! As a supplier of Footwear Metal Testers, I often get asked about the response time of these nifty machines. So, let's dive right into it and break down what response time means in the context of a Footwear Metal Tester.

First off, what is response time? Well, in simple terms, it's the time it takes for the metal tester to detect the presence of metal and give an appropriate signal or take action. For a Footwear Metal Tester, this is crucial because it directly impacts the efficiency and effectiveness of the quality control process in the footwear manufacturing industry.

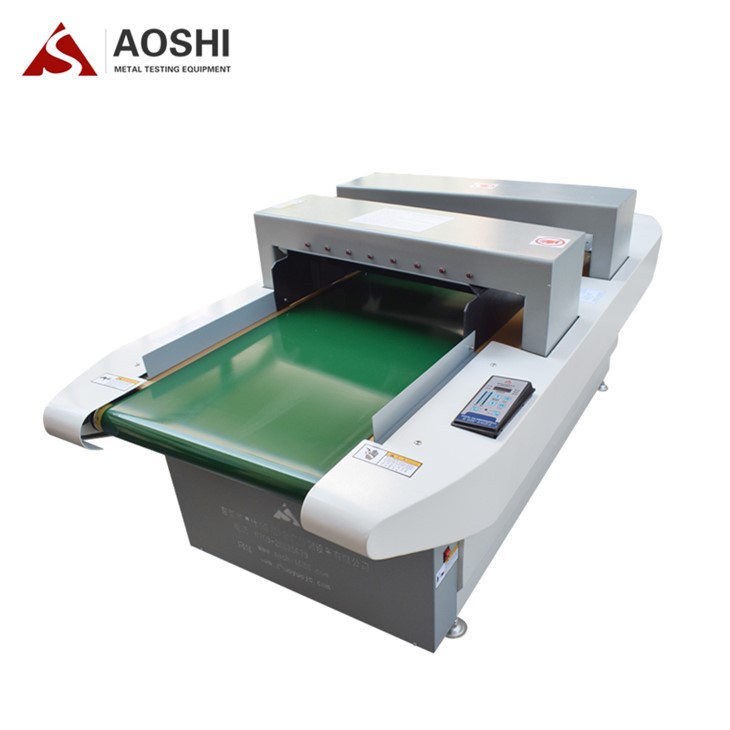

When a shoe passes through the metal tester, there are a few things happening behind the scenes. The machine emits an electromagnetic field, and when a piece of metal enters this field, it disrupts the field. The sensors in the metal tester pick up this disruption and then trigger a response. This response could be an alarm going off, a conveyor belt stopping, or some other action depending on how the machine is set up.

The response time of a Footwear Metal Tester can vary depending on several factors. One of the main factors is the type of metal being detected. Different metals have different electrical conductivity properties, which can affect how quickly the machine can detect them. For example, ferrous metals like iron are generally easier to detect than non - ferrous metals like aluminum because they have higher magnetic permeability.

Another factor is the size of the metal object. Smaller metal pieces are more difficult to detect and may require a longer response time. This is because the disruption they cause to the electromagnetic field is less significant compared to larger metal objects.

The sensitivity setting of the metal tester also plays a big role. If the sensitivity is set too low, the machine may miss small metal pieces, but if it's set too high, it may give false alarms. Finding the right balance is key to getting an optimal response time.

Now, let's talk about why a fast response time is so important. In a busy footwear manufacturing plant, time is money. A quick response time means that defective shoes can be identified and removed from the production line as soon as possible. This helps to prevent faulty products from reaching the market, which can save the company a lot of money in terms of recalls and customer complaints.

Moreover, a fast response time also improves the overall efficiency of the production process. With a short response time, the conveyor belt can keep moving at a relatively high speed, allowing more shoes to be tested in a shorter period.

As a supplier, we understand the importance of having a Footwear Metal Tester with a reliable and fast response time. That's why we offer a range of high - quality metal testers that are designed to meet the specific needs of the footwear industry.

In addition to Footwear Metal Testers, we also have other related products. For instance, if you're looking for a Non Driving Non - woven Needle Detector, you can check out this Non Driving Non - woven Needle Detector. It's a great tool for detecting needles in non - woven materials, which is important for ensuring product safety.

We also have a Wide Width Needle Inspection Machine. This machine is perfect for inspecting wider materials and can provide accurate and fast detection of metal needles.

And if you need a more advanced solution, our Double Probe Needle Detector is a great option. It uses two probes to increase the detection accuracy and can handle a variety of materials.

When it comes to choosing a Footwear Metal Tester, it's important to consider the response time along with other factors such as sensitivity, reliability, and ease of use. We're here to help you make the right choice. Our team of experts can provide you with all the information you need and help you select the best machine for your specific requirements.

If you're in the market for a Footwear Metal Tester or any of our other products, don't hesitate to get in touch with us. We're always happy to have a chat about your needs and see how we can help you improve your quality control process. Whether you're a small - scale footwear manufacturer or a large - scale production facility, we have the right solution for you.

In conclusion, the response time of a Footwear Metal Tester is a critical factor that can have a significant impact on the quality and efficiency of your production process. By choosing a high - quality metal tester with a fast response time, you can ensure that your products meet the highest standards and keep your customers happy. So, if you're interested in learning more or making a purchase, reach out to us and let's start the conversation.

References:

- Industry reports on footwear manufacturing quality control

- Technical manuals of Footwear Metal Testers