What is the maximum number of footwear that a Footwear Metal Tester can test per hour?

As a trusted supplier of Footwear Metal Testers, I often encounter inquiries from customers regarding the testing capacity of our machines. The question of "What is the maximum number of footwear that a Footwear Metal Tester can test per hour?" is a crucial one for businesses in the footwear industry, as it directly impacts productivity and efficiency. In this blog post, I will delve into the factors that influence the testing speed of Footwear Metal Testers and provide insights into the maximum testing capacity.

Factors Affecting Testing Speed

The testing speed of a Footwear Metal Tester is influenced by several key factors, including the type of machine, the complexity of the footwear design, the sensitivity setting, and the operator's proficiency. Let's take a closer look at each of these factors:

Type of Machine

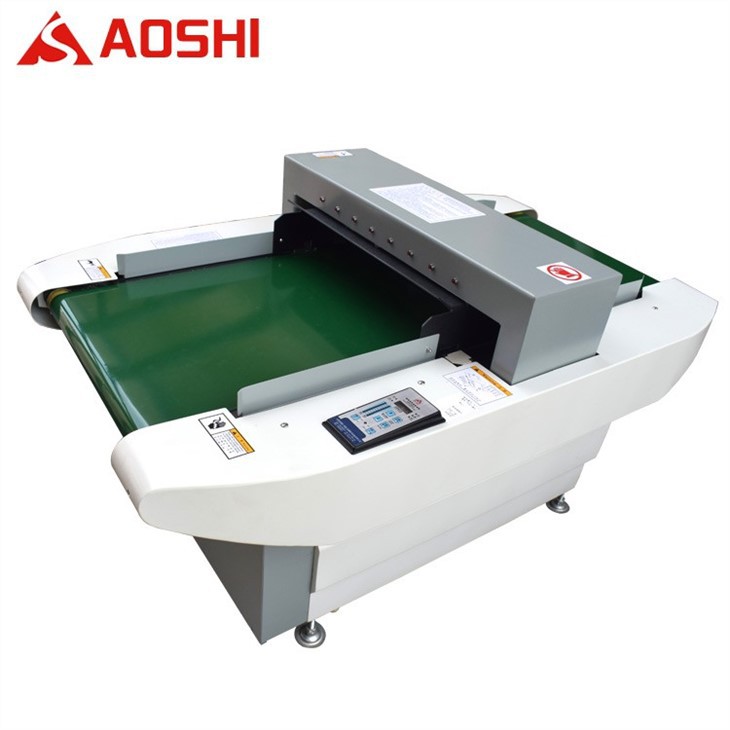

There are different types of Footwear Metal Testers available in the market, each with its own unique features and capabilities. Some machines are designed for high-speed testing, while others are more suitable for precision testing. For example, the Double Probe Needle Detector is a high-speed machine that can test multiple pairs of footwear simultaneously, making it ideal for large-scale production environments. On the other hand, the Metal Needle Inspector is a more precise machine that is designed to detect even the smallest metal particles in footwear, but it may have a slower testing speed.

Complexity of Footwear Design

The complexity of the footwear design can also affect the testing speed of a Footwear Metal Tester. Footwear with intricate designs, such as those with multiple layers, zippers, or decorations, may require more time to test than simple designs. This is because the machine needs to scan the entire surface of the footwear to ensure that there are no metal particles present. Additionally, footwear with thick soles or heavy materials may also slow down the testing process, as the machine needs to penetrate through the material to detect any metal.

Sensitivity Setting

The sensitivity setting of a Footwear Metal Tester is another important factor that can affect the testing speed. A higher sensitivity setting will allow the machine to detect smaller metal particles, but it may also increase the likelihood of false alarms. On the other hand, a lower sensitivity setting may reduce the number of false alarms, but it may also miss some small metal particles. Therefore, it is important to find the right balance between sensitivity and testing speed to ensure accurate and efficient testing.

Operator's Proficiency

The operator's proficiency also plays a crucial role in the testing speed of a Footwear Metal Tester. A well-trained operator who is familiar with the machine's operation and functions can perform the testing process more quickly and accurately than an inexperienced operator. Additionally, an operator who is able to handle the footwear properly and place it correctly on the testing platform can also improve the testing speed.

Maximum Testing Capacity

Based on the factors mentioned above, the maximum number of footwear that a Footwear Metal Tester can test per hour can vary significantly. In general, a high-speed Footwear Metal Tester can test up to 600 pairs of footwear per hour, while a more precise machine may have a testing capacity of up to 300 pairs of footwear per hour. However, these numbers are only estimates and can be affected by the specific conditions of the testing environment, such as the complexity of the footwear design, the sensitivity setting, and the operator's proficiency.

It is important to note that the maximum testing capacity of a Footwear Metal Tester is not the only factor to consider when choosing a machine. Other factors, such as the accuracy of the testing results, the reliability of the machine, and the cost of the machine, should also be taken into account. Therefore, it is recommended to consult with a professional supplier who can provide you with detailed information and guidance on choosing the right Footwear Metal Tester for your business.

Choosing the Right Footwear Metal Tester

When choosing a Footwear Metal Tester, it is important to consider your specific needs and requirements. Here are some tips to help you choose the right machine:

Determine Your Testing Requirements

Before choosing a Footwear Metal Tester, you need to determine your testing requirements, such as the type of footwear you need to test, the size of the footwear, the sensitivity level you need, and the testing speed you require. This will help you narrow down your options and choose a machine that is suitable for your business.

Consider the Type of Machine

As mentioned earlier, there are different types of Footwear Metal Testers available in the market, each with its own unique features and capabilities. You need to consider the type of machine that is most suitable for your testing requirements. For example, if you need to test large volumes of footwear quickly, a high-speed machine may be more suitable for you. On the other hand, if you need to detect small metal particles in footwear, a more precise machine may be required.

Look for a Reliable Supplier

When choosing a Footwear Metal Tester, it is important to look for a reliable supplier who has a good reputation in the industry. A reliable supplier will be able to provide you with high-quality machines, excellent customer service, and technical support. Additionally, a reliable supplier will also be able to offer you a warranty on the machine, which will give you peace of mind and protect your investment.

Compare Prices and Features

Finally, you need to compare the prices and features of different Footwear Metal Testers before making a decision. This will help you find the best machine for your budget and requirements. However, it is important to remember that the cheapest machine may not always be the best option, as it may not have the features and capabilities you need.

Conclusion

In conclusion, the maximum number of footwear that a Footwear Metal Tester can test per hour can vary significantly depending on several factors, such as the type of machine, the complexity of the footwear design, the sensitivity setting, and the operator's proficiency. When choosing a Footwear Metal Tester, it is important to consider your specific needs and requirements, as well as other factors, such as the accuracy of the testing results, the reliability of the machine, and the cost of the machine. By following these tips, you can choose the right Footwear Metal Tester for your business and ensure accurate and efficient testing.

If you are interested in learning more about our Footwear Metal Testers or would like to discuss your specific needs and requirements, please feel free to contact us. Our team of experts will be happy to provide you with detailed information and guidance on choosing the right machine for your business.