Hey there! As a supplier of Footwear Metal Testers, I often get asked about the frequency of calibration required for these nifty machines. It's a crucial question, and in this blog, I'll break it down for you.

First off, let's understand why calibration is so important. A Footwear Metal Tester is designed to detect any metal objects in footwear, such as needles, pins, or other small metal fragments. This is super important for safety reasons, especially in industries where metal contamination can pose a serious risk to consumers. If the tester isn't calibrated correctly, it might miss these metal objects, which could lead to some pretty big problems down the line.

So, how often should you calibrate your Footwear Metal Tester? Well, there's no one - size - fits - all answer. It depends on several factors.

Usage Frequency

One of the biggest factors is how often you use the machine. If you're running a high - volume production line and the Footwear Metal Tester is in use all day, every day, you'll probably need to calibrate it more frequently than if it's only used occasionally. For a busy production environment, I'd recommend calibrating at least once a day. This ensures that the machine is performing at its best and can accurately detect any metal contaminants.

Let's say you have a factory that produces hundreds of pairs of shoes every day. The constant use of the tester can cause wear and tear on its components, which might affect its accuracy. By calibrating daily, you can catch any issues early and make sure that your footwear meets the required safety standards.

Environmental Conditions

The environment in which the Footwear Metal Tester is used also plays a role. If the machine is located in an area with high humidity, extreme temperatures, or a lot of dust, it can impact the calibration. For example, high humidity can cause corrosion on the internal components of the tester, while extreme temperatures can affect the electrical properties of its sensors.

In a hot and humid factory, I'd suggest calibrating the tester every few days. This helps to account for any changes in the machine's performance due to the environmental conditions. On the other hand, if the tester is kept in a controlled environment with stable temperature and low humidity, you might be able to get away with calibrating it once a week.

Manufacturer's Recommendations

Another important factor is the manufacturer's recommendations. Different models of Footwear Metal Testers may have different calibration requirements. Some manufacturers might recommend calibrating their machines after a certain number of tests or after a specific period of time. It's always a good idea to read the user manual that comes with the machine and follow the manufacturer's guidelines.

For instance, if the manufacturer says that the tester should be calibrated after every 1000 tests, you should stick to that schedule. This ensures that you're following the best practices for your specific machine and can help to extend its lifespan.

Quality Control Standards

Industry quality control standards also influence the calibration frequency. In some industries, there are strict regulations regarding the detection of metal contaminants in footwear. For example, in the medical footwear industry, the standards are very high because any metal contamination could pose a serious risk to patients.

If your business is subject to these strict quality control standards, you'll likely need to calibrate your Footwear Metal Tester more frequently. This could mean calibrating multiple times a day or even after every batch of shoes is tested. Meeting these standards is essential for maintaining the reputation of your brand and ensuring the safety of your customers.

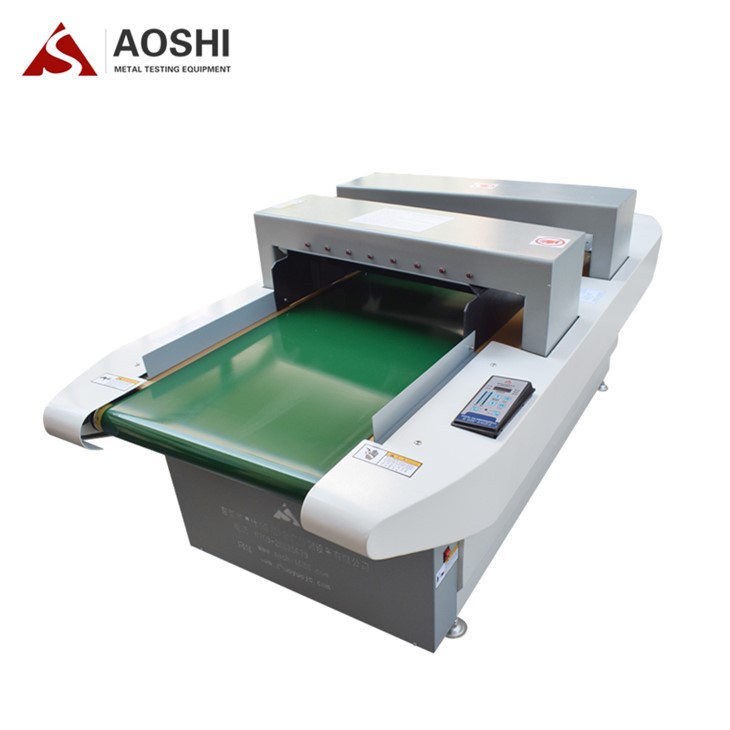

Now, let's talk about some of the different types of Footwear Metal Testers we offer. We have the Double Probe Needle Detector, which is great for detecting small metal objects in footwear. It has two probes that work together to provide more accurate detection.

Our Wide Width Needle Inspection Machine is ideal for larger production lines. It can handle wider footwear and has a high - speed detection system, which is perfect for high - volume manufacturing.

And then there's the Metal Needle Inspector, which is a versatile machine that can be used for both small - scale and large - scale production. It's easy to operate and provides reliable results.

If you're in the market for a Footwear Metal Tester or need to upgrade your existing machine, I'd love to have a chat with you. We can discuss your specific requirements and help you choose the right tester for your business. Whether you're a small shoe workshop or a large - scale manufacturer, we have the expertise and the products to meet your needs.

Calibrating your Footwear Metal Tester is an important part of ensuring the safety and quality of your footwear. By considering factors like usage frequency, environmental conditions, manufacturer's recommendations, and quality control standards, you can determine the right calibration schedule for your machine. And if you're looking for a reliable Footwear Metal Tester, don't hesitate to reach out. We're here to help you make the best decision for your business.

References

- General knowledge of Footwear Metal Tester technology and industry standards.

- User manuals of various Footwear Metal Tester models.