As a reputable supplier of Metal Needle Detectors, I often encounter inquiries about the detection depth of these essential devices. Understanding the detection depth is crucial for industries that rely on metal needle detectors to ensure product safety and quality. In this blog post, I will delve into the factors that influence the detection depth of a metal needle detector and provide insights to help you make informed decisions for your business.

Understanding Metal Needle Detectors

Before we discuss detection depth, let's briefly review how metal needle detectors work. These machines are designed to detect the presence of metal needles or other ferrous and non - ferrous metals in various products. They operate on the principle of electromagnetic induction. When a metal object passes through the detection field of the machine, it disrupts the magnetic field, triggering an alarm or activating a rejection mechanism.

Metal needle detectors are widely used in industries such as textiles, food processing, pharmaceuticals, and plastics. In the textile industry, for example, they help prevent needles from being accidentally left in garments, which could pose a serious safety hazard to consumers. In the food industry, they ensure that no metal contaminants are present in food products, maintaining food safety standards.

Factors Affecting Detection Depth

The detection depth of a metal needle detector is not a fixed value and can be influenced by several factors:

1. Type of Metal

Different metals have different magnetic and electrical properties, which affect their detectability. Ferrous metals, such as iron and steel, are generally easier to detect than non - ferrous metals like aluminum, copper, and stainless steel. Ferrous metals are highly magnetic, and they cause a significant disruption in the magnetic field of the detector, allowing for deeper detection. Non - ferrous metals, on the other hand, have lower magnetic permeability, and their detection depth may be shallower.

2. Size and Shape of the Metal Object

The size and shape of the metal needle or object also play a crucial role in detection depth. Larger metal objects are easier to detect than smaller ones. A thicker and longer needle will have a greater impact on the magnetic field and can be detected at a greater depth compared to a thin and short needle. Additionally, irregularly shaped objects may be more difficult to detect than objects with a regular shape, as their magnetic field interactions can be more complex.

3. Product Characteristics

The nature of the product being inspected can significantly affect the detection depth. Products with high moisture content, high salt content, or those that are electrically conductive can interfere with the magnetic field of the detector. For example, in the food industry, wet or salty products may reduce the detection depth of the metal needle detector. Similarly, products with a high density or complex structure may also pose challenges to detection, as they can absorb or scatter the magnetic field.

4. Detector Design and Technology

The design and technology of the metal needle detector itself are important factors. Advanced detectors with high - frequency coils and sophisticated signal processing algorithms can achieve greater detection depths. These detectors are more sensitive to small metal objects and can better distinguish between metal contaminants and background noise. Additionally, the size and configuration of the detection head can also impact the detection depth. A larger detection head may provide a wider detection area but may also have limitations in terms of depth.

Measuring Detection Depth

The detection depth of a metal needle detector is typically measured in millimeters or inches. Manufacturers usually provide a specification for the maximum detection depth under ideal conditions. However, it's important to note that these specifications are often based on tests using standard metal samples in a controlled environment. In real - world applications, the actual detection depth may be lower due to the factors mentioned above.

To accurately measure the detection depth for a specific application, it's recommended to conduct on - site tests using the actual products and metal samples. This will give you a more realistic understanding of the detector's performance in your production environment.

Our Metal Needle Detector Range

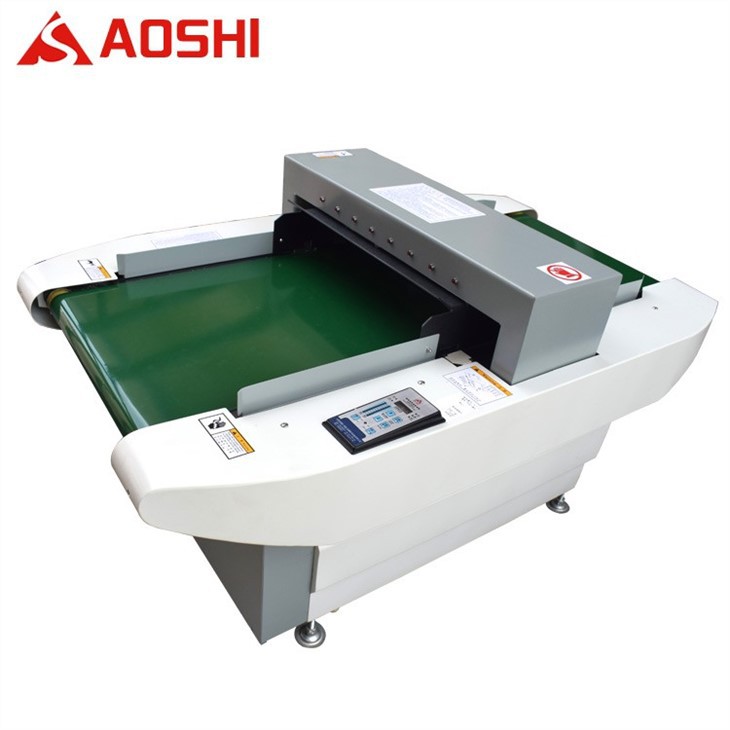

At our company, we offer a wide range of metal needle detectors to meet the diverse needs of different industries. Our Wide Width Needle Inspection Machine is designed for high - volume production lines, providing a large inspection area while maintaining high sensitivity. It can effectively detect metal needles and other contaminants in wide - width products such as carpets, fabrics, and non - woven materials.

Our Metal Needle Inspector is a versatile and compact detector suitable for small - to - medium - sized production facilities. It offers reliable detection performance and can be easily integrated into existing production lines.

For the non - woven industry, our Non Driving Non - woven Needle Detector is specifically designed to meet the unique requirements of non - woven product inspection. It provides high - speed and accurate detection of metal needles in non - woven materials, ensuring product quality and safety.

Optimizing Detection Depth

To maximize the detection depth of your metal needle detector, consider the following tips:

1. Product Preparation

If possible, pre - process the product to reduce factors that may interfere with detection. For example, drying wet products or reducing the salt content can improve the detection performance. Additionally, ensuring that the product is evenly distributed and properly aligned during inspection can also enhance the accuracy of detection.

2. Detector Calibration

Regularly calibrate your metal needle detector to ensure its optimal performance. Calibration involves adjusting the detector settings to account for changes in the product characteristics, environmental conditions, and detector sensitivity. Follow the manufacturer's instructions for calibration and perform it at regular intervals.

3. Maintenance and Upgrades

Keep your metal needle detector well - maintained by cleaning the detection head, checking the electrical connections, and replacing worn - out parts. Additionally, consider upgrading your detector to the latest model or technology to take advantage of improved detection capabilities.

Conclusion

The detection depth of a metal needle detector is a complex parameter that is influenced by multiple factors. Understanding these factors is essential for selecting the right detector for your application and ensuring effective metal contaminant detection. At our company, we are committed to providing high - quality metal needle detectors with excellent detection performance.

If you are interested in learning more about our metal needle detectors or have specific requirements for your business, we invite you to contact us for a detailed consultation. Our team of experts will be happy to assist you in choosing the most suitable detector and optimizing its performance for your production line.

References

- "Principles of Metal Detection", Metal Detection Handbook, [Publisher]

- "Factors Affecting Metal Detection in Food Products", Journal of Food Safety, [Volume], [Issue]

- "Advanced Metal Detection Technologies for Industrial Applications", Proceedings of the International Conference on Industrial Automation, [Year]