When it comes to ensuring product safety, especially in industries like textiles, food, and pharmaceuticals, a metal needle detector is an indispensable tool. As a trusted supplier of metal needle detectors, I understand the importance of using these machines safely and effectively. In this blog, I'll share some crucial safety precautions that every user should follow when operating a metal needle detector.

Pre - operation Precautions

1. Machine Installation

Before using the metal needle detector, it's essential to install it correctly. Place the detector on a stable and level surface. Uneven ground can cause the machine to vibrate during operation, which may affect its detection accuracy and even lead to mechanical failures. Make sure the installation location is away from large metal objects, strong magnetic fields, and high - frequency interference sources. For example, avoid installing the detector near large motors or transformers. These external factors can generate magnetic fields that interfere with the normal operation of the metal needle detector, resulting in false alarms or missed detections.

2. Power Supply Check

Always check the power supply before turning on the machine. Ensure that the voltage and frequency of the power source match the requirements of the metal needle detector. Using an inappropriate power supply can damage the internal components of the machine and pose a safety hazard. Additionally, make sure the power cord is in good condition, without any exposed wires or signs of damage. A damaged power cord can cause electrical leakage, which is extremely dangerous.

3. Operator Training

All operators should receive proper training before using the metal needle detector. They need to understand the basic principles of the detector, its operating procedures, and safety precautions. Training should cover topics such as how to set the detection sensitivity, how to calibrate the machine, and how to handle different types of products. Untrained operators may not be able to use the detector correctly, which can lead to inaccurate detections and potential safety risks.

Operation Precautions

1. Product Preparation

Before passing products through the metal needle detector, make sure they are clean and dry. Moisture or dirt on the products can affect the detection results. For example, in the textile industry, wet fabrics may cause false alarms due to the conductivity of water. Also, ensure that the products are within the size and weight limits specified by the detector. Overloading the machine with oversized or overweight products can damage the conveyor belt or other components of the detector.

2. Sensitivity Setting

Set the detection sensitivity according to the type of products and the requirements of the production process. If the sensitivity is set too low, small metal needles may not be detected, which can pose a serious threat to consumers. On the other hand, if the sensitivity is set too high, the detector may generate false alarms, reducing work efficiency. Our Double Probe Needle Detector offers precise sensitivity adjustment, allowing you to customize the detection level for different products.

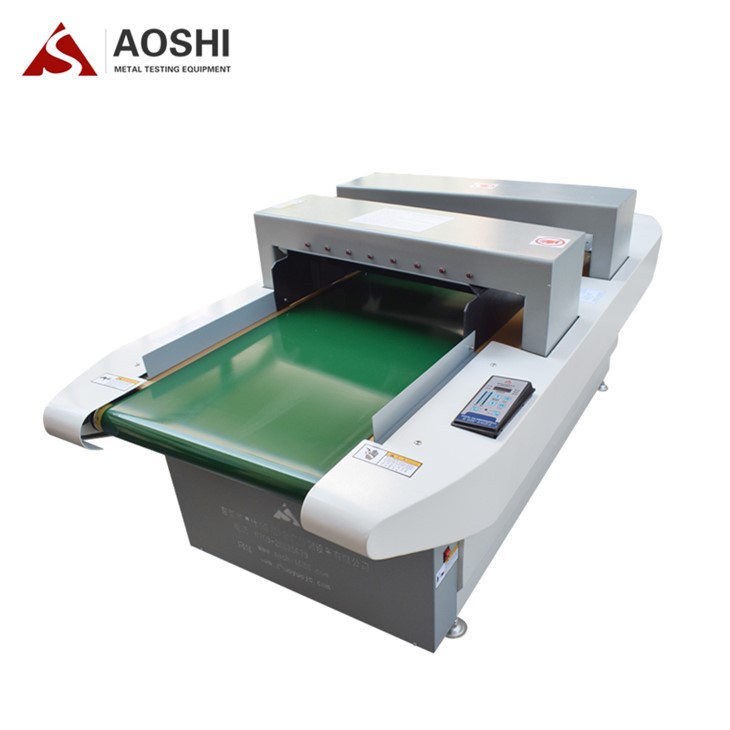

3. Conveyor Belt Operation

If the metal needle detector is equipped with a conveyor belt, pay attention to its operation. Make sure the conveyor belt is running smoothly and at a proper speed. A too - fast conveyor belt may cause products to bounce or slide, which can affect the detection accuracy. Regularly check the conveyor belt for any signs of wear or damage, such as cracks or fraying. Replace the conveyor belt immediately if any problems are found.

4. Monitoring During Operation

Continuously monitor the operation of the metal needle detector during the production process. Watch for any abnormal noises, vibrations, or error messages on the control panel. If any problems are detected, stop the machine immediately and troubleshoot the issue. For example, if the detector suddenly starts making a loud noise, it may indicate a mechanical problem that needs to be addressed promptly.

Post - operation Precautions

1. Machine Cleaning

After each use, clean the metal needle detector thoroughly. Remove any debris or dust from the conveyor belt, detection head, and other parts of the machine. Use a soft, dry cloth to wipe the surfaces. For stubborn dirt, you can use a mild cleaning agent, but make sure to follow the manufacturer's instructions. Cleaning the machine regularly can prevent the accumulation of dirt, which can affect its performance and lifespan.

2. Power Off

When the production is finished, turn off the metal needle detector and unplug the power cord. This not only saves energy but also reduces the risk of electrical accidents. Make sure to wait for a few minutes after turning off the machine to allow it to cool down completely before performing any maintenance or cleaning work.

3. Maintenance and Calibration

Regular maintenance and calibration are essential for the proper functioning of the metal needle detector. Follow the manufacturer's recommended maintenance schedule, which may include tasks such as lubricating the moving parts, checking the electrical connections, and replacing worn - out components. Calibrate the machine regularly using standard test samples to ensure its detection accuracy. Our Wide Width Needle Inspection Machine and Long Strip Needle Inspection Machine are designed for easy maintenance and calibration, ensuring long - term reliable performance.

Conclusion

Using a metal needle detector safely is crucial for ensuring product quality and consumer safety. By following these safety precautions in the pre - operation, operation, and post - operation stages, you can minimize the risks associated with using the machine and ensure its optimal performance. As a leading supplier of metal needle detectors, we are committed to providing high - quality products and comprehensive technical support. If you have any questions about our products or need further information on safety precautions, please feel free to contact us for procurement and in - depth discussions.

References

- Manufacturer's manuals for metal needle detectors

- Industry standards and regulations related to metal detection in different sectors (textiles, food, pharmaceuticals, etc.)

- Technical research papers on the principles and applications of metal needle detectors