As a supplier of Footwear Metal Testers, I often encounter inquiries from customers regarding the compliance of our products with relevant safety standards. This is a crucial concern, as ensuring the safety of footwear products is of utmost importance in the industry. In this blog post, I will delve into the topic of whether a Footwear Metal Tester is compliant with relevant safety standards, exploring the key factors and considerations.

Understanding the Importance of Safety Standards

Safety standards play a vital role in the footwear industry. They are established to protect consumers from potential hazards associated with metal objects in footwear, such as needles, pins, or other metallic fragments. These objects can pose a significant risk of injury, especially to the feet, if they are not detected and removed during the manufacturing process.

Compliance with safety standards is not only a legal requirement in many countries but also a moral obligation for footwear manufacturers. By using a Footwear Metal Tester that meets relevant safety standards, manufacturers can demonstrate their commitment to producing safe and high - quality products.

Relevant Safety Standards for Footwear Metal Testers

There are several safety standards that Footwear Metal Testers should comply with. One of the most well - known standards is the ISO (International Organization for Standardization) series. ISO standards provide a framework for quality management and safety in various industries, including footwear manufacturing.

In addition to ISO standards, there are also regional and national standards. For example, in the European Union, the CE marking indicates that a product complies with EU safety, health, and environmental protection requirements. In the United States, the Consumer Product Safety Commission (CPSC) sets safety standards for consumer products, including footwear.

How Our Footwear Metal Testers Ensure Compliance

Our company takes compliance with safety standards very seriously. We have designed our Footwear Metal Testers to meet and exceed the requirements of major international and regional safety standards.

Advanced Detection Technology

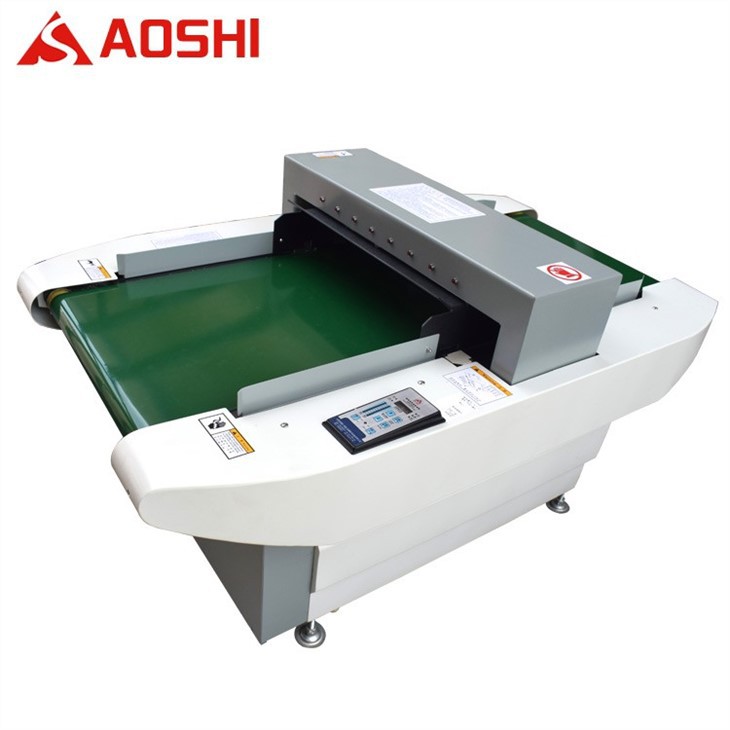

Our Footwear Metal Testers are equipped with state - of - the - art detection technology. They use high - sensitivity sensors that can detect even the smallest metal objects in footwear. The sensors are calibrated to accurately identify different types of metals, including ferrous, non - ferrous, and stainless steel.

For example, our Long Strip Needle Inspection Machine is specifically designed to detect long and thin metal objects, such as needles, in long strips of footwear materials. It has a high - speed detection system that can quickly and accurately identify any metal contaminants, ensuring that the final product is safe for consumers.

Quality Control and Testing

Before leaving our factory, each Footwear Metal Tester undergoes rigorous quality control and testing procedures. We test our machines using a variety of metal samples to ensure that they can detect different sizes and types of metals. Our quality control team also checks the overall performance and stability of the machines to ensure that they meet our high standards.

We also conduct regular internal audits to ensure that our manufacturing processes are in line with relevant safety standards. This helps us to identify and address any potential issues before they become problems.

Continuous Improvement

The field of metal detection technology is constantly evolving, and so are the safety standards. We are committed to continuous improvement and invest heavily in research and development. Our engineers are constantly working on improving the performance and functionality of our Footwear Metal Testers to ensure that they remain compliant with the latest safety standards.

Benefits of Using Compliant Footwear Metal Testers

Consumer Safety

The most obvious benefit of using a compliant Footwear Metal Tester is the protection of consumers. By detecting and removing metal objects from footwear, we can prevent potential injuries to consumers, such as puncture wounds or infections.

Legal Compliance

Using a compliant Footwear Metal Tester helps footwear manufacturers to comply with legal requirements. This can save them from potential legal issues, such as product recalls or lawsuits, which can be costly and damaging to their reputation.

Brand Reputation

Manufacturers who use compliant Footwear Metal Testers can build a positive brand reputation. Consumers are more likely to trust and purchase products from companies that prioritize safety. A good brand reputation can lead to increased customer loyalty and higher sales.

Conclusion

In conclusion, our Footwear Metal Testers are fully compliant with relevant safety standards. Through advanced detection technology, strict quality control, and continuous improvement, we ensure that our machines can effectively detect and remove metal objects from footwear, protecting consumers and helping manufacturers to meet legal requirements.

If you are in the footwear manufacturing industry and are looking for a reliable Footwear Metal Tester, we invite you to contact us for more information. We are ready to provide you with professional advice and high - quality products to meet your specific needs.

References

- International Organization for Standardization (ISO). ISO standards for quality management and safety.

- European Union. CE marking requirements for consumer products.

- Consumer Product Safety Commission (CPSC). Safety standards for consumer products in the United States.