Hey there! As a supplier of Metal Needle Inspectors, I'm stoked to share with you how these nifty machines can detect metal in rubber products. It's a super important process, especially in industries where rubber products are used, like automotive, manufacturing, and even consumer goods. You know, a small piece of metal in a rubber product can lead to big problems, from product failure to safety hazards. So, let's dig into how Metal Needle Inspectors work their magic.

The Basics of Metal Detection in Rubber Products

First off, let's talk about why we need to detect metal in rubber products. In the manufacturing process, it's possible for small metal pieces, like needles, staples, or metal shavings, to accidentally end up in the rubber. This can happen due to a variety of reasons, such as faulty machinery, improper handling, or contamination in the raw materials.

When it comes to detecting this metal, Metal Needle Inspectors are the go - to solution. These machines use advanced technology to identify even the tiniest metal particles hidden inside rubber products. But how do they do it?

The Technology Behind Metal Needle Inspectors

There are a few different technologies that Metal Needle Inspectors commonly use. One of the most popular is electromagnetic induction. This technology is based on the principle that when a metal object enters a changing magnetic field, it generates an electrical current, also known as an eddy current.

The Metal Needle Inspector has a coil that creates a magnetic field. When a rubber product passes through this magnetic field, any metal inside it will disrupt the field and cause a change in the electrical properties of the coil. The machine's sensors detect this change and trigger an alarm or some other indicator to show that metal has been found.

Another technology is magnetic field sensors. These sensors can detect the presence of magnetic materials, like iron and steel. The Metal Needle Inspector has a set of sensors that are sensitive to the magnetic fields generated by metal objects. As the rubber product moves through the inspection area, the sensors continuously monitor the magnetic field. If a metal object is present, it will distort the magnetic field, and the sensors will pick up this distortion.

There's also a type of detection method that uses X - rays. Although not as common as electromagnetic induction and magnetic field sensors, X - ray technology can be very effective in detecting non - magnetic metals as well as magnetic ones. X - rays can penetrate the rubber and create an image of the internal structure of the product. By analyzing this image, the machine can identify any metal objects that are hidden inside.

Our Range of Metal Needle Inspectors

Now, let me tell you about the different types of Metal Needle Inspectors we offer. We have the Long Strip Needle Inspection Machine. This is perfect for inspecting long, narrow rubber products, like rubber strips or hoses. It can quickly and accurately detect any metal particles along the entire length of the strip.

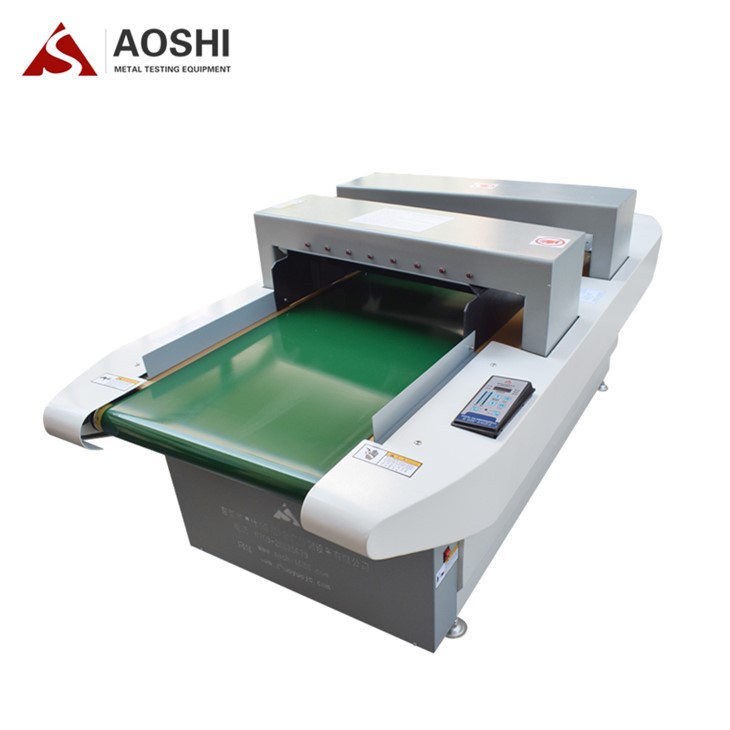

Then, there's the Wide Width Needle Inspection Machine. This one is great for wider rubber products, such as rubber sheets or mats. It has a wider inspection area, so it can cover more surface area at once, making the inspection process faster and more efficient.

We also have the Double Probe Needle Detector. This machine uses two probes to detect metal, which increases the accuracy and sensitivity of the inspection. It can detect even the smallest metal particles, ensuring that your rubber products are metal - free.

The Inspection Process

So, how exactly does the inspection process work? First, you need to set up the Metal Needle Inspector according to the specifications of your rubber products. This includes adjusting the sensitivity of the machine, depending on the size and type of metal you're trying to detect.

Once the machine is set up, you place the rubber products on the conveyor belt or in the inspection area. The machine then starts to scan the products as they move through the detection zone. If a metal object is detected, the machine will stop the conveyor belt, sound an alarm, or use some other method to indicate the presence of metal.

The operator can then remove the product with the metal contamination and take appropriate action, such as re - inspecting it or discarding it. After that, the inspection process can continue with the remaining products.

Benefits of Using Our Metal Needle Inspectors

Using our Metal Needle Inspectors comes with a whole bunch of benefits. First of all, it helps to improve the quality of your rubber products. By detecting and removing metal contaminants, you can ensure that your products meet the highest quality standards. This, in turn, can increase customer satisfaction and reduce the likelihood of product returns or recalls.

Secondly, it enhances safety. Metal particles in rubber products can pose a serious safety risk, especially in industries where the products are used in critical applications. For example, in the automotive industry, a metal piece in a rubber part could cause a mechanical failure, which could lead to an accident. By using our Metal Needle Inspectors, you can minimize these safety risks.

Finally, it saves you money in the long run. Detecting metal contaminants early in the manufacturing process can prevent costly production delays and waste. You don't have to worry about producing defective products that will need to be scrapped or reworked, which can save you a significant amount of time and resources.

Contact Us for Your Metal Detection Needs

If you're in the market for a reliable Metal Needle Inspector for your rubber product manufacturing, look no further. Our machines are high - quality, efficient, and easy to use. We have a team of experts who can help you choose the right machine for your specific needs and provide you with all the support you need.

Reach out to us to start a conversation about your metal detection requirements. We're here to assist you every step of the way, from the initial consultation to after - sales service. Let's work together to ensure the quality and safety of your rubber products.

References

- "Metal Detection in Manufacturing Processes." Manufacturing Technology Journal.

- "Advanced Sensors for Quality Control in Rubber Production." Sensors and Actuators Magazine.

- "Electromagnetic Induction in Metal Detection." Physics of Industrial Applications Journal.