Hey there! I'm a supplier of Metal Needle Inspectors, and today I wanna chat about how these nifty machines detect metal in rubber - metal composite products. It's a topic that's super important in industries where the presence of metal contaminants can cause big problems.

Let's start with the basics. Rubber - metal composite products are everywhere. You'll find them in automotive parts, industrial machinery, and even some consumer goods. But if there's a metal needle or other metal debris hidden inside these products, it can lead to failures, safety hazards, and a whole bunch of headaches for manufacturers. That's where our Metal Needle Inspector comes in.

The Principle of Detection

At the heart of a Metal Needle Inspector is the principle of electromagnetic induction. You know, that thing you might have learned about in high - school physics? Well, it's put to good use here. The inspector creates a magnetic field around the area where the rubber - metal composite product is passing through. When a metal object, like a needle, enters this magnetic field, it disrupts the field.

This disruption is then detected by sensors in the inspector. The sensors are super sensitive and can pick up even the tiniest changes in the magnetic field. Once the disruption is detected, the inspector's system sends a signal. This signal can be used to trigger an alarm, stop the production line, or divert the contaminated product for further inspection.

Types of Metal Detection

There are a couple of different types of metal detection methods that our Metal Needle Inspectors can use. One is the balanced coil method. In this method, there are three coils in the detector. One is the transmitter coil, which creates the magnetic field. The other two are receiver coils. Under normal conditions, the signals from the receiver coils are balanced. But when a metal object enters the magnetic field, the balance is disrupted, and the detector can tell there's metal present.

Another method is the pulse induction method. This method sends short pulses of current through a coil, creating a magnetic field. When a metal object is in the field, it generates its own magnetic field in response to the pulses. The detector then measures the changes in the magnetic field caused by the object's response. This method is great for detecting all types of metals, including non - ferrous metals like aluminum and copper.

Detecting Metal in Rubber - Metal Composites

Now, detecting metal in rubber - metal composite products can be a bit tricky. The rubber part of the product can sometimes interfere with the detection process. Rubber is a non - conductive material, but it can still affect the magnetic field to some extent. That's why our Metal Needle Inspectors are designed with advanced algorithms and signal processing techniques.

These algorithms help to filter out the background noise caused by the rubber and focus on the signals that are likely to be from metal objects. The inspectors are also calibrated to work with different types of rubber - metal composites. For example, if the rubber has a high density or contains certain additives, the inspector can be adjusted to account for these factors.

Our Product Range

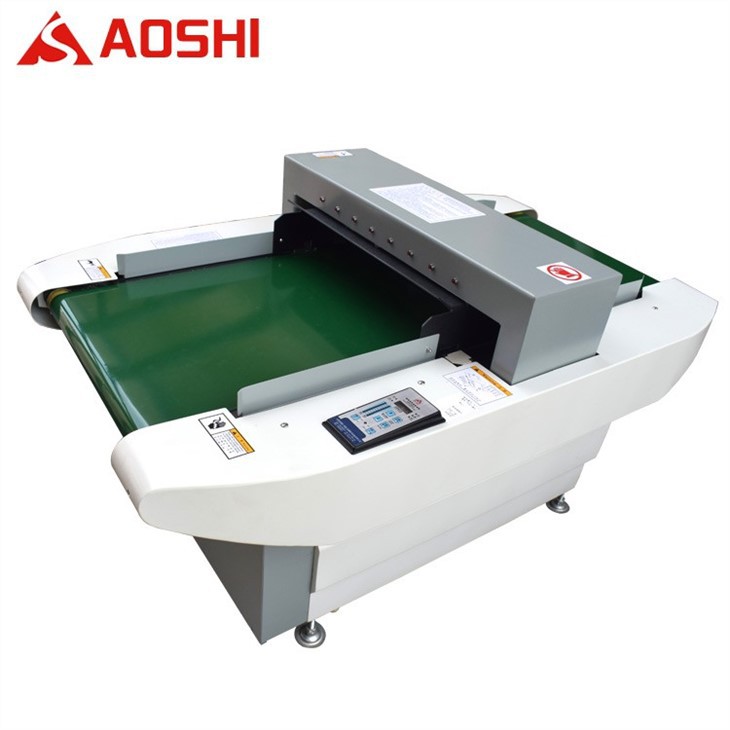

We offer a variety of Metal Needle Inspectors to suit different needs. One of our popular models is the Long Strip Needle Inspection Machine. This machine is perfect for inspecting long strips of rubber - metal composite materials, like those used in gaskets or seals. It has a long inspection area and can handle high - speed production lines.

Another great option is the High Gantry Needle Detector. This detector is designed for larger rubber - metal composite products. It has a high - clearance gantry, which means it can accommodate products of different sizes and shapes. It's also very accurate and can detect even small metal needles hidden deep inside the product.

Benefits of Using Our Metal Needle Inspectors

Using our Metal Needle Inspectors has a whole bunch of benefits. First of all, it helps to improve the quality of your rubber - metal composite products. By detecting and removing metal contaminants, you can reduce the risk of product failures and recalls. This, in turn, can save you a lot of money in the long run.

Secondly, it enhances safety. In industries like automotive and aerospace, the presence of metal needles in rubber - metal composite parts can pose a serious safety hazard. Our inspectors can help to ensure that these parts are free from metal contaminants, making your products safer for use.

Finally, it increases efficiency. By quickly detecting and removing contaminated products, you can keep your production line running smoothly. You won't have to waste time and resources on products that are likely to fail due to metal contamination.

Why Choose Our Company

We've been in the business of manufacturing Metal Needle Inspectors for a long time. We've got a team of experts who know everything there is to know about metal detection technology. Our products are built to last and are constantly being updated with the latest technology.

We also offer great customer support. If you have any questions about our Metal Needle Inspectors, or if you need help with installation or calibration, our team is always here to help. We believe in building long - term relationships with our customers, and we'll do everything we can to make sure you're satisfied with our products.

Contact Us for Purchase

If you're in the market for a Metal Needle Inspector for your rubber - metal composite product manufacturing process, we'd love to hear from you. Whether you need a Long Strip Needle Inspection Machine for your high - speed production line or a High Gantry Needle Detector for larger products, we've got the right solution for you.

Just reach out to us to start a conversation about your specific needs. We can provide you with more detailed information, product specifications, and pricing. Let's work together to make your production process more efficient, your products safer, and your business more successful.

References

- "Metal Detection Handbook" by John W. H. Price

- "Electromagnetic Nondestructive Evaluation" by David A. Jiles