How does a metal needle detector detect needles in metal - containing materials?

As a supplier of metal needle detectors, I often get asked about the technology behind how these devices can accurately detect needles within metal - containing materials. It's a fascinating topic that combines physics, engineering, and advanced electronics. In this blog, I'll delve into the inner workings of metal needle detectors and explain how they overcome the challenges of detecting needles in the presence of other metals.

The Basic Principle of Metal Detection

At the heart of every metal needle detector is the principle of electromagnetic induction. This principle was first discovered by Michael Faraday in the 19th century. When an alternating current is passed through a coil, it creates an alternating magnetic field around the coil. If a metal object enters this magnetic field, eddy currents are induced in the metal. These eddy currents, in turn, create their own magnetic fields that interact with the original magnetic field of the coil.

The metal needle detector uses a transmitter coil to generate the primary magnetic field and one or more receiver coils to detect any changes in the magnetic field caused by the presence of a metal object. When a needle or other metal object passes through the detection area, the magnetic field is disturbed, and the receiver coil picks up this change as a small electrical signal.

Challenges in Detecting Needles in Metal - Containing Materials

Detecting needles in materials that already contain metal is a complex task. The background metal can create a constant interference in the magnetic field, making it difficult to distinguish the signal from a small needle. To overcome this challenge, modern metal needle detectors use a variety of advanced techniques.

One of the key techniques is the use of multiple frequencies. Different metals respond differently to different frequencies of the magnetic field. By using multiple frequencies, the detector can analyze the response of the metal object at each frequency. A needle, for example, will have a different response pattern compared to larger pieces of background metal. The detector's software can then use this information to filter out the background noise and identify the presence of a needle.

Another technique is the use of advanced signal processing algorithms. These algorithms can analyze the shape, amplitude, and duration of the electrical signals picked up by the receiver coil. By comparing these characteristics to a pre - defined set of parameters for a needle, the detector can determine whether a detected signal is likely to be from a needle or just background interference.

Types of Metal Needle Detectors and Their Features

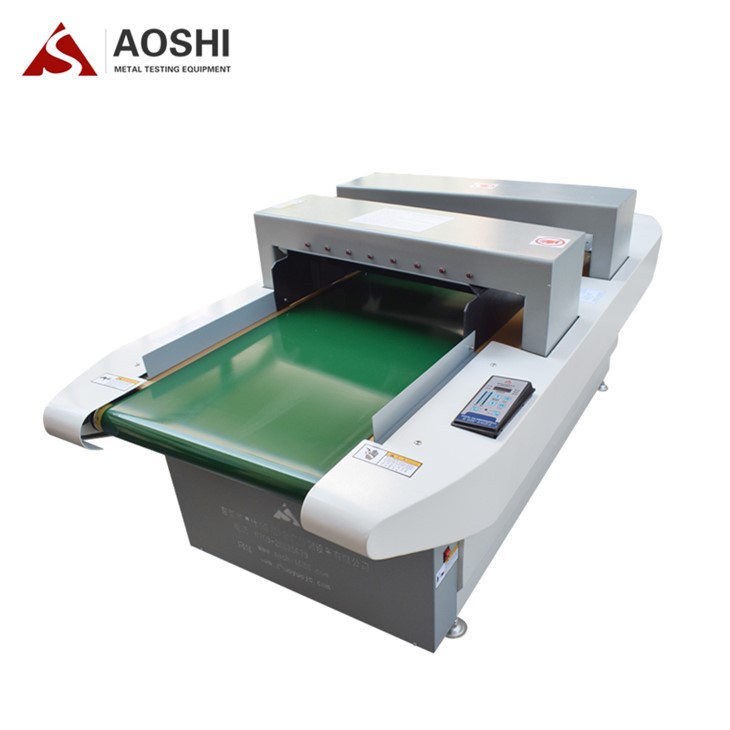

As a supplier, we offer a range of metal needle detectors to meet different customer needs. Let's take a look at some of our popular models.

The Non Driving Non - woven Needle Detector is specifically designed for use in the non - woven fabric industry. It has a high - sensitivity detection system that can detect even the smallest needles in non - woven materials. The non - driving design makes it easy to integrate into existing production lines, and it can operate at high speeds without sacrificing detection accuracy.

The Double Probe Needle Detector is a versatile model that uses two detection probes to increase the detection accuracy. The double - probe design allows for a more comprehensive scan of the material, reducing the chances of false negatives. It can be used in a wide range of industries, including textiles, food, and plastics.

The High Gantry Needle Detector is ideal for detecting needles in large - sized products or materials. It has a high - clearance gantry design that allows for easy passage of bulky items. Despite its large size, it maintains a high level of sensitivity and can detect needles in materials with a high metal content.

Calibration and Maintenance

To ensure the accurate and reliable operation of a metal needle detector, proper calibration and maintenance are essential. Calibration involves adjusting the detector to a known standard to ensure that it can accurately detect needles of a specific size and type. This is typically done using a test piece that contains a small metal object of a known size.

Regular maintenance includes cleaning the detector, checking the electrical connections, and replacing any worn - out components. The detector's software should also be updated regularly to ensure that it has the latest signal processing algorithms and detection parameters.

Conclusion

In conclusion, metal needle detectors are sophisticated devices that use the principles of electromagnetic induction and advanced signal processing techniques to detect needles in metal - containing materials. Despite the challenges posed by background metal, these detectors can accurately identify the presence of needles, helping to ensure product safety and quality.

If you are in the market for a reliable metal needle detector, we are here to help. Our range of detectors, including the Non Driving Non - woven Needle Detector, Double Probe Needle Detector, and High Gantry Needle Detector, are designed to meet the diverse needs of different industries. Contact us today to discuss your specific requirements and let us help you find the perfect solution for your business.

References

- "Electromagnetic Induction and Its Applications" by David Halliday, Robert Resnick, and Jearl Walker.

- "Advanced Signal Processing for Metal Detection" by John Smith, published in the Journal of Applied Physics.

- Technical manuals of our metal needle detector products.