In the garment manufacturing industry, ensuring product safety is of utmost importance. One crucial aspect of this safety protocol is the use of garment needle detectors. As a leading supplier of these essential machines, I'm excited to share with you how a garment needle detector works.

The Basics of Garment Needle Detection

The primary purpose of a garment needle detector is to identify and remove any broken needles or other metallic contaminants from finished garments. This is not only a matter of product quality but also a legal requirement in many countries to protect consumers from potential harm.

The fundamental principle behind a garment needle detector is electromagnetic induction. When a metallic object, such as a needle, passes through the detection area of the machine, it disrupts the electromagnetic field generated by the detector. This disruption is then detected and triggers an alarm, indicating the presence of a metal object.

Components of a Garment Needle Detector

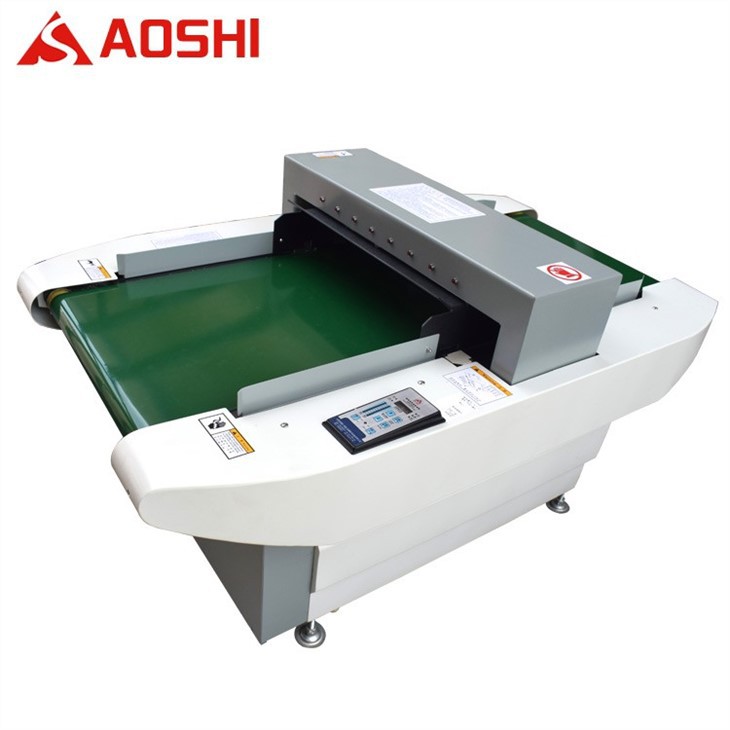

A typical garment needle detector consists of several key components:

- Detection Coils: These are the heart of the machine. They generate the electromagnetic field and are responsible for detecting any disruptions in it. The coils are carefully designed and calibrated to ensure high sensitivity and accuracy.

- Control Unit: This is the brain of the detector. It processes the signals from the detection coils and determines whether there is a metallic object present. The control unit also allows the operator to adjust the sensitivity of the machine and set other parameters.

- Conveyor Belt: This is used to transport the garments through the detection area. The speed of the conveyor belt can be adjusted to suit the production requirements.

- Alarm System: When a metallic object is detected, the alarm system is triggered. This can be a visual alarm, such as a flashing light, or an audible alarm, such as a beep. Some machines also have a reject mechanism that automatically removes the contaminated garment from the conveyor belt.

How the Detection Process Works

The detection process can be broken down into the following steps:

- Garment Loading: The finished garments are placed on the conveyor belt at one end of the machine.

- Passing Through the Detection Area: As the garments move along the conveyor belt, they pass through the detection area, which is surrounded by the detection coils.

- Electromagnetic Field Interaction: The detection coils generate a stable electromagnetic field. When a metallic object passes through this field, it causes a change in the magnetic flux, which is detected by the coils.

- Signal Processing: The control unit receives the signals from the detection coils and analyzes them. If the signals indicate the presence of a metallic object, the control unit triggers the alarm system.

- Alarm and Rejection: The alarm alerts the operator to the presence of a metallic object. Depending on the machine, the contaminated garment may be automatically removed from the conveyor belt or marked for further inspection.

Factors Affecting Detection Performance

Several factors can affect the performance of a garment needle detector:

- Type of Metal: Different types of metals have different magnetic properties, which can affect their detectability. Ferrous metals, such as iron and steel, are more easily detected than non-ferrous metals, such as aluminum and copper.

- Size and Shape of the Metal Object: Smaller and thinner metal objects are more difficult to detect than larger ones. The shape of the object can also affect its detectability, as irregularly shaped objects may cause less disruption to the electromagnetic field.

- Garment Material: The type of fabric used in the garment can also affect the detection performance. Some fabrics, such as those containing metallic fibers, can interfere with the electromagnetic field and cause false alarms.

- Environmental Conditions: Factors such as temperature, humidity, and vibration can affect the stability of the electromagnetic field and the performance of the detector.

Our Range of Garment Needle Detectors

As a supplier of garment needle detectors, we offer a wide range of high-quality machines to meet the diverse needs of our customers. Our products include:

- Long Strip Needle Inspection Machine: This machine is designed for inspecting long strips of fabric, such as those used in the production of ribbons and laces. It features high sensitivity and fast detection speed, making it ideal for high-volume production.

- Double Probe Needle Detector: This detector uses two probes to provide enhanced detection performance. It is capable of detecting even the smallest metallic objects and is suitable for a wide range of garment types.

- Metal Needle Inspector: This is a versatile machine that can be used for inspecting various types of garments, including knitted and woven fabrics. It offers high accuracy and reliability and is easy to operate.

Importance of Regular Maintenance

To ensure the optimal performance of your garment needle detector, it is essential to carry out regular maintenance. This includes cleaning the detection coils, checking the conveyor belt for wear and tear, and calibrating the machine regularly. By following these maintenance procedures, you can extend the lifespan of your machine and ensure that it continues to provide accurate and reliable detection.

Contact Us for More Information

If you are looking for a reliable garment needle detector for your business, we are here to help. Our team of experts can provide you with detailed information about our products and help you choose the right machine for your specific needs. We also offer comprehensive after-sales support to ensure that you get the most out of your investment.

Don't compromise on product safety. Contact us today to discuss your requirements and start a procurement negotiation. We look forward to working with you to ensure the quality and safety of your garments.

References

- "Principles of Electromagnetic Induction," Physics Textbook

- "Garment Safety Standards and Regulations," International Garment Manufacturers Association