Hey there! As a supplier of Metal Needle Detectors, I often get asked if these nifty devices can be used in the toy manufacturing industry. Well, the short answer is a resounding yes! In this blog post, I'm gonna dive deep into why metal needle detectors are not just useful but essential in the world of toy making.

First off, let's talk about safety. Toys are meant to bring joy and entertainment to kids, but they should also be safe. You know, there are all sorts of potential hazards during the manufacturing process. For instance, needles or other small metal objects could accidentally end up in the toys. These can pose a serious choking hazard or cause physical injury to children if swallowed or stepped on. That's where metal needle detectors come in. They act as a safety net, ensuring that no metal contaminants make it into the final product.

One of the key features of a good metal needle detector is its sensitivity. Our Double Probe Needle Detector is designed to detect even the tiniest metal fragments. It uses advanced technology to scan toys thoroughly, picking up on any metal that shouldn't be there. This high - sensitivity is crucial because even a small piece of metal can be dangerous for a child.

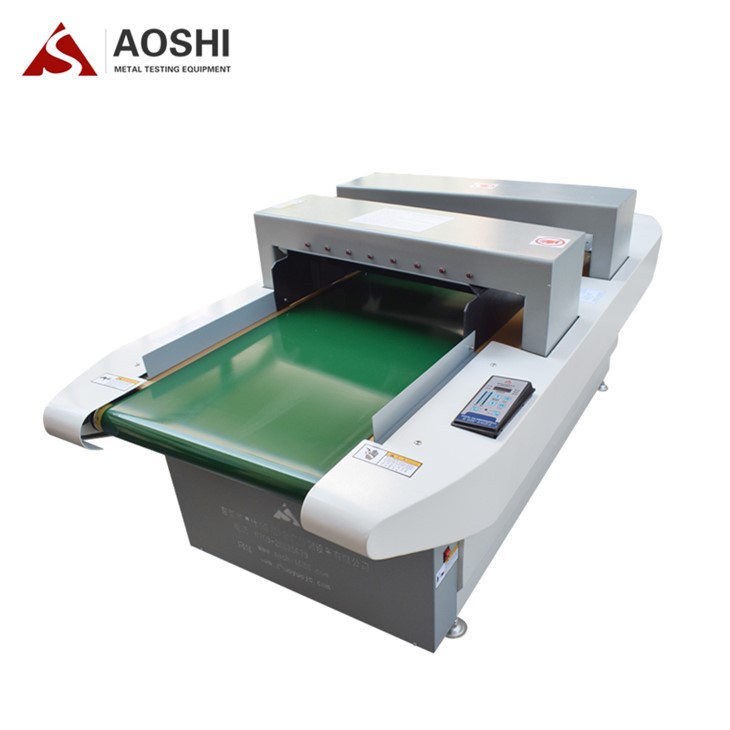

Another important aspect is the efficiency of these detectors. In a toy manufacturing plant, time is money. You can't afford to have long delays in the production line. Our Metal Needle Inspector is built to be fast and reliable. It can quickly scan toys as they move along the conveyor belt, allowing for a seamless production process. This means that you can keep your production rates high while still maintaining a high level of safety.

Now, let's consider the different types of toys. There are plush toys, plastic toys, and even electronic toys. Each type has its own unique challenges when it comes to metal detection. For plush toys, there's a risk of needles getting stuck in the stuffing. Our Long Strip Needle Inspection Machine is specifically designed to handle these types of toys. It can penetrate through the soft material and detect any metal hidden inside.

For plastic toys, the detector needs to be able to distinguish between the plastic and any metal contaminants. Our detectors use sophisticated algorithms to do just that. They can accurately identify metal objects while ignoring the plastic components of the toy. This ensures that you don't get false alarms, which can slow down the production process.

Electronic toys present a different set of challenges. They often contain small metal parts that are supposed to be there, like wires and connectors. Our metal needle detectors are calibrated to differentiate between these legitimate metal components and any unwanted metal fragments. This way, you can be sure that only the dangerous metal is detected.

In addition to safety, using a metal needle detector can also help with quality control. By ensuring that your toys are free of metal contaminants, you're improving the overall quality of your products. This can lead to better customer satisfaction and fewer product recalls. In today's competitive market, having a reputation for high - quality, safe toys can give you a real edge.

Let's talk about compliance. There are strict regulations in place regarding the safety of toys. Many countries have laws that require toy manufacturers to ensure that their products are free of hazardous materials, including metal contaminants. By using a metal needle detector, you're making sure that your business is compliant with these regulations. This can save you from potential legal issues and costly fines.

Now, I know what you might be thinking. "These detectors must be expensive and hard to maintain." Well, that's not the case. Our metal needle detectors are designed to be cost - effective. They have a long lifespan, and the maintenance requirements are minimal. We also offer excellent customer support, so if you ever run into any issues, our team is ready to help.

So, if you're in the toy manufacturing industry, investing in a metal needle detector is a no - brainer. It's an investment in the safety of children, the quality of your products, and the success of your business. Whether you're a small - scale toy maker or a large - scale manufacturer, our range of metal needle detectors can meet your needs.

If you're interested in learning more about our products or want to discuss how a metal needle detector can fit into your production process, don't hesitate to get in touch. We're always happy to have a chat and help you find the best solution for your business.

References

- Industry reports on toy safety regulations

- Technical specifications of our metal needle detectors