Are toy needle detectors easy to operate?

As a supplier of toy needle detectors, I often get asked whether these devices are easy to operate. The answer is a resounding yes! Toy needle detectors are designed to be user - friendly, making them accessible even to those with minimal technical knowledge.

Understanding the Basics of Toy Needle Detectors

Toy needle detectors are essential pieces of equipment in the toy manufacturing industry. Their primary function is to detect the presence of metal needles or other ferrous contaminants in toys. This is crucial for ensuring the safety of children who play with these toys. A single needle left in a toy can pose a serious choking or injury hazard.

The operation of a toy needle detector is based on electromagnetic principles. When a toy passes through the detector's scanning area, the detector creates an electromagnetic field. If there is a metal object such as a needle within the field, it will disrupt the field, triggering an alarm. This simple yet effective mechanism forms the basis of how these detectors work.

Key Features that Make Them Easy to Operate

Intuitive Control Panels

Most modern toy needle detectors come with intuitive control panels. These panels are usually equipped with clear buttons and displays. For example, the power button is prominently labeled, and there are often indicators that show the detector's status, such as whether it is on, off, or in a calibration mode. The control panel also allows users to adjust settings such as sensitivity. With just a few presses of a button, operators can increase or decrease the detector's sensitivity depending on the type of toys being scanned.

Simple Calibration Process

Calibration is an important step in ensuring the accurate operation of a toy needle detector. However, it is not a complex process. In fact, many of our detectors have an automatic calibration feature. Operators simply need to place a known test sample (a toy with a small metal object of a specific size) in the scanning area and press the calibration button. The detector will then adjust its settings to accurately detect objects of that size and similar ones. This automatic calibration reduces the chances of human error and makes the process quick and straightforward.

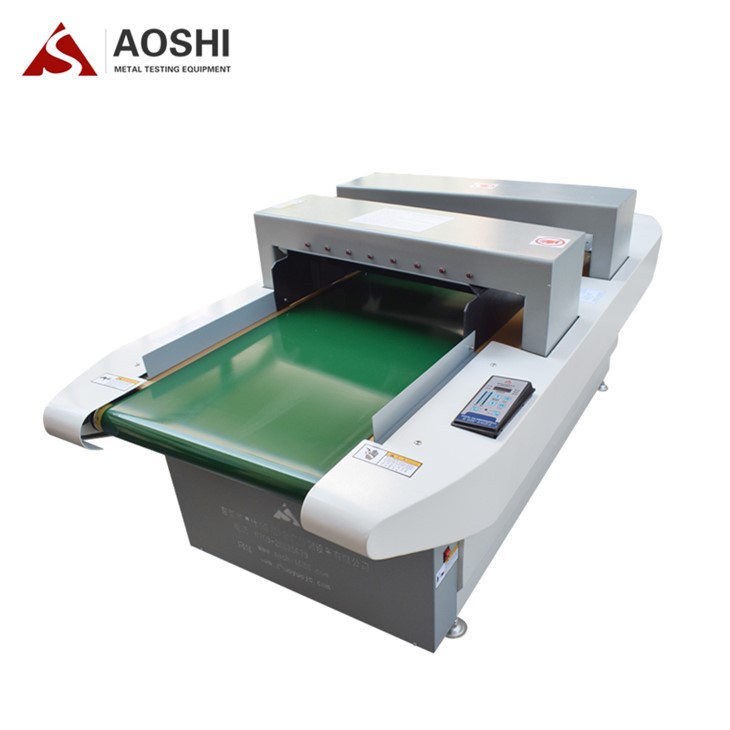

Easy Loading and Unloading

The design of toy needle detectors takes into account the ease of loading and unloading toys. They are typically equipped with conveyor belts or feeding mechanisms that smoothly move toys through the scanning area. The height and width of the scanning area are also designed to accommodate different sizes of toys. For smaller toys, operators can easily place them on the conveyor belt one by one. For larger toys, there is usually enough space to ensure that the entire toy can pass through the detector without getting stuck.

Different Types of Toy Needle Detectors and Their Ease of Operation

Non Driving Non - woven Needle Detector

The Non Driving Non - woven Needle Detector is a great example of a user - friendly toy needle detector. This type of detector is suitable for detecting needles in non - woven materials used in toys. It has a simple structure and is easy to install. The non - driving feature means that it does not require complex motor controls. Operators can simply place the non - woven material or the toy made from it on the detection platform, and the detector will quickly scan for any metal contaminants.

Double Probe Needle Detector

The Double Probe Needle Detector offers enhanced detection capabilities. It uses two probes to scan the toys from different angles, increasing the accuracy of detection. Despite its advanced technology, it is still easy to operate. The control panel allows operators to manage both probes independently if needed. The double - probe design also reduces the chances of false negatives, making the overall operation more reliable.

High Gantry Needle Detector

The High Gantry Needle Detector is designed for larger toys or products. Its high - gantry design provides enough space for tall or bulky items to pass through. The operation of this detector is similar to other types. The conveyor belt system is easy to control, and the sensitivity settings can be adjusted according to the specific requirements of the toys being scanned.

Training and Support

While toy needle detectors are easy to operate, we also provide comprehensive training and support to our customers. Our training programs cover everything from basic operation to advanced troubleshooting. We offer on - site training where our technicians will visit the customer's facility and train their staff in person. We also provide online resources such as video tutorials and user manuals. These resources can be accessed at any time, allowing operators to refresh their knowledge or learn new features of the detector.

Conclusion

In conclusion, toy needle detectors are indeed easy to operate. Their intuitive control panels, simple calibration processes, and user - friendly designs make them accessible to a wide range of users. Whether you are a small - scale toy manufacturer or a large - scale production facility, our toy needle detectors can be easily integrated into your production line.

If you are interested in purchasing a toy needle detector or have any questions about their operation, we encourage you to contact us for a detailed discussion. Our team of experts is ready to assist you in finding the right detector for your specific needs and guiding you through the procurement process.

References

- "Principles of Electromagnetic Detection in Industrial Equipment", Journal of Industrial Technology, 20XX.

- "User - Friendly Design in Manufacturing Equipment", International Journal of Manufacturing Design, 20XX.